1851 Great Exhibition: Official Catalogue: Class VI.: Robert Plummer

74. PLUMMER, ROBERT, Newcastle-upon-Tyne — Inventor.

Patent machines, viz., rotary disc scutching machine, for flax, hemp, &c; with straw holders, and with straw to scutch. Flax-breaking machine, for flax straw previous to being scutched. Flax-cutting machine, for preparing flax for the cut-flax heckling machine. Heckling machine, for dressing flax, hemp, etc.; with flax holders, and with flax to dress. Flax holders, of various improved forms, showing the application of gutta percha to these implements.

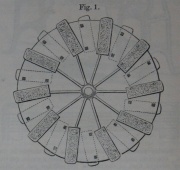

The engraving exhibits the metal disc for scutching flax, with the brushes fitted to it. The disc is seen in Fig. 1 from above.

The cut, Fig. 2, represents a front elevation of the rotary disc scutching mill. A is an axle having its bearings in an independent framing, k and k i, of metal; the upper portion being made open with a lining of dials, l, l; the metal piece m, m, at the front end being secured by three bolts car be readily removed for the purpose by changing the brushes in the discs. The framing is stiffened by cross pieces, n, n, b, b, are pulleys by which a rotatory motion is imparted to the axles. The top, i, of the scutching board, h, is placed a little above the centre of the axle, A. The heckle or comb of is composed of steel wire.

Fig. 3 is a front, and Fig. 4 is a side elevation of an improved flax-breaking machine. The letters h, c, and d, are placed upon the grooved metal rollers, to which the flax is presented, as seen in fig. 326, by the direction of e arrow.

Figs. 7 and 8 represent a side and end elevation of the double cylinder heckling machine, adapted to the dressing cut or short flax, in which elastic brushes are combined with rigid heckles. There are two revolving cylinders, b1, b1, mounted in a framework a, a; added to their peripheries are sets of rigid heckles, c1, intermixed with the sets of elastic brushes c, c (in any way that may be deemed most advisable). The cylinders are also made to revolve inwardly or in opposite directions, and the rows of brushes and heckles on the one cylinder are placed in an alternating order in regard to those of the other cylinder, as before described. There are also loose stripping bars with guards, that, besides regulating the depth to which the heckles or brushes shall penetrate, doff or throw down the tow from the brushes and heckles, and two smaller cylinders b, fitted with brushes for cleaning the working brushes and heckles c, c1.

One of the cylinders, b1, may, if required, be made to oscillate by means of the link hi, hi, which, as it rises and falls with the lifter to which it is attached, moves the cylinder in a horizontal direction to and from the other cylinder; the bearings of the oscillating cylinder being made to slide and attached by a rod to the radius arm to which the stud pin of the wheel m' is fixed, the whole of the wheels, k3, l1, m1, and n1, are thus kept in gear, to answer the varying position of the oscillating cylinder. Rotation is given to the rotating parts of this machine as in the one first described, but the holder is made to traverse or move forward in the trough (which movement may also be applied to the brushing machine) by the combination of a bell crank movement with the rising and falling motion of the trough, as afterwards described. The mechanism for lifting the trough h, is shown in fig. 8, and consists of a combination of pinions k2, k3, and wheels m, n, cam p, straps o, pulleys q, and levers r, s, such as is ordinarily used in heckling machines, and well known.

When the trough is raised, it pushes up a rod x, which is connected to the long arm of the bell crank y, mounted on a standard affixed to the top of the frame-work a, when a weight W, which is attached to the opposite end of the arm, falls over, and causes the short arm of the bell crank to pull in a rod z1, which draws forward a finger bar x (of the ordinary construction) to an extent sufficient to advance the holder the breadth of one set of heckles or brushes. The tow and shive or dirt doffed or thrown down from the heckles or brushes is in this case received upon an endless chain of bars t, t (instead of the inclined grating represented in the machine first described), which bars extend the whole length of the machine under the heckles and brushes, and are connected together by two side bands t2, t2. The chain of bars revolves round two friction pulleys v, v, and takes into two pinions u, u (one on each side); by means of which pinions rotation is given to the chain from the same first mover by which the other parts of the machine are put in motion. The shive or dirt falls through between the bars on to the floor, while the tow is carried forward on the top of the bars, and delivered into the trough V. To separate the tow doffed from each set of heckles or brushes, the space between the endless chain of bars and the cylinders is divided by partitions aa, aa, fig. 1, into as many compartments as there are sets of heckles or brushes; and the receiving trough T1 is also divided into a corresponding number of compartments.

A view of the holder, for this machine, is given in fig. 5, a cross section, and fig. 6, a longitudinal section. It consists of two plates, Nos. 1 and 2, connected traversely by a screw bolt S, and having flanges A, A, at their upper edges, by means of which they are supported in the trough h. The plate No. 2 has two flanges B, B, one on each end, which come within the flanges A, A, of the plate No. 1, and thereby confine the streak at the edges. The inner face of the plate No. 2 is planed perfectly true, and covered with felt, cloth, or some other soft or yielding material; but the plate No. 1 is made on its inner face with flat beads C, and flat grooves D, in alternate order, so that the streak of flax or other material may be the more firmly compressed between the plates without being unduly crimped. At their under edges E, the plates are chamfered off to admit of the holder coming lower down. By this mode of construction, the pins or studs ordinarily made use of to confine the outer edges of the streaks, are dispensed with, and a greater breadth is obtained whereon to spread the streaks, and the holder is also narrowed and rendered more easy to work.

Raw materials in illustration:— English flax seed. Flax straw from Northumberland and Durham; and flax fibre and dressed line. Russian, Irish, and New Zealand flax, as imported, and when rescutched; also Russian hemp rescutched.

Manufactures in illustration:— Yarn, from flax dressed by the patent heckling machine; and canvas woven from the same. Yarns, spun on Peter Fairbairn and Co.'s (Leeds) new patent long line, rotatory gill, spinning frame; and canvas made from these yarns.