Llanddulas Viaduct

On the London and North Western Railway Chester - Holyhead line, close to the shore.

The first railway viaduct had seven brick arches, each spanning 28 ft, and crossed the River Dulas. This was normally a small stream, but the viaduct was brought down on 17 August 1879 by the river in flood.

It was decided to make a temporary line a short distance inland, with a wooden bridge. In the morning of the 19th, work started in earnest. 600-700 men were divided into three gangs, each working 16 hours. Initially no accommodation or food were provided, but this was remedied, the company supplying railway carriages and food.

The temporary works were completed by the end of the week, and on Sunday the 24th of August, at 2 pm, the first goods train passed over, followed the next day by passenger trains; the interruption to the traffic lasted only a week, during which time passengers and luggage were transferred by road from the station at Abergele to that of Llanddulas. The temporary works were carried out by Mr. Footner of the LNWR, in three hours under seven days, including two days of enforced inactivity while the flood was subsiding.

Meanwhile the massive amount of fallen masonry and other debris of the old bridge was removed.

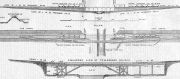

he distance to be spanned was 224 ft., and it was decided that the superstructure should consist entirely of steel, the girders resting on six new piers built on the old foundations. The piers were 4ft. thick above base, and built of glazed bricks, in strong mortar (composed of one part Portland cement to one part of clean sand from Colwyn Bay pits). The height of the tallest pier was 50 ft. To prevent a second flood undermining the piers of the new bridge, Mr. Smith, the District Engineer, had them connected together near their foundations by masonry inverts, protected up and down stream by aprons.

Progress was helped by an early use of electric lighting. Serrin 's lamps were placed up on the pillasters of the old abutments, with two Gramme machines on the Abergele side, and one Siemens machine on the Llanddulas side, the former being equal to about 4000 candles each, and the latter to 5000 candles, each machine being worked at about 800 rpm. On the Abergele side a wooden shed was erected for the electric machines, and for two engines which were employed to work the same. One engine of 8 HP for the two Gramme's machines, and one of 6 HP for the Siemens; and one boiler was employed to feed the two engines, the water supply being pumped up from the stream below by a small donkey engine fixed on the bank of the stream.

F. W. Webb, the chief mechanical engineer, commenced the manufacture of the steel plates for the superstructure. There were in all 42 girders, each 32 ft. long, besides transverse girders, flooring plates, etc., but the work was simplified by adopting the bold device of rolling all the plates and angle irons for the top and bottom girders in single lengths. No cover or joint plates were used. Each span had four steel girders, one under each line of rails, and two lattice outside girders. In the space of just seven days the whole of the material was turned out ready for erection, the steel having been manufactured, rolled, and worked up at Crewe; as rapidly as possible the material was despatched to Llanddulas, so that no time should be lost in their erection, which was completed seven days after the last of the steelwork had been delivered to site. In somewhat less than a month from the time of the accident, the traffic was diverted on to the re-established line. The official inspection of the Board of Trade took place on September 22, when it was found that the deflection in the centre of the spans under a passing load was only 1/16in. The responsible officers were F. W. Webb, Frank Stevenson, the chief civil engineer, Mr. Smith, the district engineer, and Mr. Footner

Points were installed to switch the up and down lines onto the single track. Each train was provided with one or two banking/braking engines.

The new viaduct was opened on 17 September, one month after the collapse.

The above information is mainly drawn from illustrated articles in The Engineer and Engineering, referenced below.

Reference is made in Engineering[3] to the electrical apparatus of the type supplied by Marshall, Sons and Co to the order of Crompton and Fawkes. It shows a Marshall 6 HP portable engine with a two-wheeled carriage attached to the front, supporting a Gramme dynamo driven by two belts from the two flywheels. In this case 3.5 to 3.75 IHP was required to provide the 6000 candle power supplied by the machine featured, in the situation where the lamps were mounted close to the machine (minimum resistance). Attached to the carriage were three drums holding 300 yards of cable. The lamps used were modifications of the Serrin regulator type. The engine's two flywheels had extra heavy rims. Hartnell' s automatic expansion valve gear controlled by the governors gave 'remarkable uniformity of speed under varying loads, and is exceedingly steady and free from any tendency to pulsate or hunt.'

The viaduct was reconstructed at some point (1970s?), using the 1879 piers.