BTH: Electric Motors: Difference between revisions

No edit summary |

No edit summary |

||

| Line 3: | Line 3: | ||

[[image:Im201106GTM-BTH3.jpg|thumb| Electric Winding Equipment at [[Geevor Mine]]. ]] | [[image:Im201106GTM-BTH3.jpg|thumb| Electric Winding Equipment at [[Geevor Mine]]. ]] | ||

[[image:Im201106GTM-BTH4.jpg|thumb| Winding gear for the Victory Shaft at [[Geevor Mine]].]] | [[image:Im201106GTM-BTH4.jpg|thumb| Winding gear for the Victory Shaft at [[Geevor Mine]].]] | ||

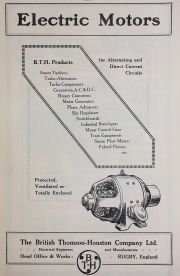

[[Image:Im1921Eng-BTH.jpg|thumb| 1921. ]] | |||

[[Image:Im1923RlyDiary-BTH.jpg|thumb| 1923. ]] | [[Image:Im1923RlyDiary-BTH.jpg|thumb| 1923. ]] | ||

[[image:Im1929v147-p600.jpg|thumb| 1929.]] | [[image:Im1929v147-p600.jpg|thumb| 1929.]] | ||

Latest revision as of 09:01, 8 May 2024

Note: This is a sub-section of BTH

1920 February. Catalogue of DC motors up to 200 h.p.[1]

1920 September. Exhibited at the Machine Tool and Engineering Exhibition at Olympia with motors for machine tool driving. [2]

1926 Received an order for six electric motor-driven centrifugal blowers, which would be the largest so far manufactured in this country. They would be used on two motor ships which John Brown and Co were constructing.[3]

1932 Produced a very large synchronous motor for the Tata Iron and Steel Co of India. Rated at 7500 HP at 94 rpm, with a peak load capability of nearly 19,000 HP. It was designed, constructed, tested and made ready for shipment in just 9 weeks.

1945 Advert for electric motors with control gear for industrial use. Fabroil silent pinions. [4]

1946 Large motors were being produced at Rugby; 'industrial motors' in Birmingham; FHP motors in Coventry and Newcastle-under-Lyme.

Continued in AEI: Electric Motors and AEI: Motor and Control Gear

See Also

Sources of Information

- ↑ The Engineer of 27th Feb 1920 p208

- ↑ The Engineer of 3rd September 1920 p233

- ↑ The Engineer 1926/07/23

- ↑ Mechanical World Year Book 1945. Published by Emmott and Co of Manchester. Advert p45 & p63