Bever and Dorling: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

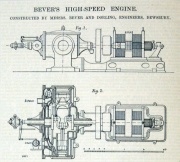

[[image:Im18880127E-Bever.jpg|thumb| | [[image:Im18880127E-Bever.jpg|thumb| 1888. Bever's high speed engine<ref>[[Engineering 1888/01/27]]</ref>]] | ||

of Dewsbury Foundry, Dewsbury. | of Dewsbury Foundry, Dewsbury. | ||

| Line 8: | Line 8: | ||

1887 Advertisement for Bever and Dorling (Late [[W. and J. Cardwell]]): Engineers, Millwrights, Iron and Brass founders, steam engines, pumps and winding gear, wheels, pulleys, pedestals, shafting.<ref>* 'Stationary Steam Engine Makers Volume 1' Compiled by George Watkins, Catalogued by A P Woolrich, Landmark Publishing Ltd. ISBN 1-84306-200-3</ref> | 1887 Advertisement for Bever and Dorling (Late [[W. and J. Cardwell]]): Engineers, Millwrights, Iron and Brass founders, steam engines, pumps and winding gear, wheels, pulleys, pedestals, shafting.<ref>* 'Stationary Steam Engine Makers Volume 1' Compiled by George Watkins, Catalogued by A P Woolrich, Landmark Publishing Ltd. ISBN 1-84306-200-3</ref> | ||

1888 BEVER's high-speed engine is single-acting with two | |||

cylinders on opposite sides of the crankshaft and | |||

coupled to cranks opposite each other. The engines | |||

are made either high pressure or compound, and the | |||

cylinders are so proportioned, that the pressures are | |||

equal on each side, thus balancing each other on the | |||

crankshaft. The high-pressure piston is connected by | |||

a straight rod to the centre crank-pin, and the low-pressure one by a forked rod to the two side crankpins ; by duly proportioning the weights of these rods and pistons, they can also be made to balance each | |||

other. ..... The engraving shows an engine exhibited by Messrs. | |||

Bever and Dorling at the Saltaire Exhibition, driving | |||

a Gulcher dynamo at 800 revolutions per minute for | |||

arc lighting.' <ref>[[Engineering 1888/01/27]]</ref>. See illustration. | |||

1909 Moved to Bowling Ironworks, Bradford<ref>[http://www.haigpit.com/page4.html Haig Colliery website]</ref> | 1909 Moved to Bowling Ironworks, Bradford<ref>[http://www.haigpit.com/page4.html Haig Colliery website]</ref> | ||

Latest revision as of 19:16, 10 February 2025

of Dewsbury Foundry, Dewsbury.

See also Bever, Dorling and Co of Bradford

1884 Patent 1666 for high speed steam engine

1887 Advertisement for Bever and Dorling (Late W. and J. Cardwell): Engineers, Millwrights, Iron and Brass founders, steam engines, pumps and winding gear, wheels, pulleys, pedestals, shafting.[2]

1888 BEVER's high-speed engine is single-acting with two cylinders on opposite sides of the crankshaft and coupled to cranks opposite each other. The engines are made either high pressure or compound, and the cylinders are so proportioned, that the pressures are equal on each side, thus balancing each other on the crankshaft. The high-pressure piston is connected by a straight rod to the centre crank-pin, and the low-pressure one by a forked rod to the two side crankpins ; by duly proportioning the weights of these rods and pistons, they can also be made to balance each other. ..... The engraving shows an engine exhibited by Messrs. Bever and Dorling at the Saltaire Exhibition, driving a Gulcher dynamo at 800 revolutions per minute for arc lighting.' [3]. See illustration.

1909 Moved to Bowling Ironworks, Bradford[4]

See Also

Sources of Information

- ↑ Engineering 1888/01/27

- ↑ * 'Stationary Steam Engine Makers Volume 1' Compiled by George Watkins, Catalogued by A P Woolrich, Landmark Publishing Ltd. ISBN 1-84306-200-3

- ↑ Engineering 1888/01/27

- ↑ Haig Colliery website