Robert Edward Phillips: On the Construction of Modern Cycles

Note: This is a sub-section of Robert Edward Phillips

Copy held in the SMC Library (with p67 part missing)

On the Construction of Modern Cycles by Robert Edward Phillips. 1885.

The Cycle industry in this country has grown with such rapidity, and has already assumed proportions of such magnitude, as to lead the author to hope that the present paper may prove of some interest to the Institution. It would not be possible within any reasonable limits to do justice to all matters connected with cycles; and he therefore purposes dealing only with their general construction: pointing out the underlying principles, and describing the various types at present made, in order to show how far these principles have been carried out, and what degree of perfection has already been attained.

Power.— On the power expended in the propulsion of cycles some experiments have already been made. In a paper read before the Royal Dublin Society, Messrs. S. J. and G. S. Stoney gave the results of a series of experiments carried out by them, which showed that the power required to propel a bicycle on an average road was between one-seventh and one-third of a horse-power, according as the speed varied between six and fourteen miles per hour. These figures must be taken only as approximate, because the experiments were made on a lever-action machine, which adapts itself more readily for attaching and working a diagram indicator than machines with a rotary action; and the author believes that a rotary-action machine would give better results.

Bicycle.— The invention of the Bicycle is universally accredited to Gavin Dalzell, a cooper by trade, living at Lesmahagow in Lanarkshire, who in 1836 first fixed a pair of cranks to one of the wheels of a "hobby horse," a vehicle which was constructed with two small wheels mounted to run in a line one before the other, and across which the rider straddled, propelling himself from the ground by his feet on either side; the addition of the cranks converted it into a bicycle, driven by working the cranks with the feet. Owing to its crude construction the machine was then rightly termed a "bone-shaker;" and it underwent no real improvement until the introduction of the "suspension" wheel, from which may be said to have sprung the modern cycle. To whom the invention of the suspension wheel is to be ascribed is somewhat uncertain; but circumstances go to show that it is due to a Past-President of this Institution, Mr. Cowper, inasmuch as in 1868, before suspension wheels were made in this country, certain improvements in velocipedes were specified by him, which cover amongst other things the suspension wheel with wire spokes, hollow felloes, and rubber tyres, and also anti-friction roller-bearings. Without these features or some modifications of them, no cycle at the present day is satisfactory.

Tricycle.— Although the Tricycle, or as it was called in early days the velocipede, was invented contemporaneously with the bicycle, it did not attract the same attention that was accorded to the bicycle until some six years later. Doubtless the perfection to which, by a slow but sure development, the narrow-gauge machine or bicycle had during that time been brought, encouraged manufacturers and others to turn their attention to the broad-gauge machine or tricycle.

Statistics.— The extent to which inventors have applied themselves to perfecting both kinds of cycles may be inferred from the fact that over a thousand patents for improvements relating to velocipedes had been applied for down to the end of 1883; whilst during the year 1884, at the commencement of which the new patent act came into force, no less than 637 applications were filed. The dimensions to which the manufacture of bicycles has grown may be gathered from the fact that there are now upwards of 170 firms who devote themselves exclusively to it, and who produce over five hundred different machines; and it is calculated that in Coventry alone, the scat of this industry, it employs three thousand men, and throughout the United Kingdom five thousand at least. The number of machines sold annually is estimated at 40,000; reckoning their average price at £20 each, a gross amount of £800,000 is attained. The capital invested in the manufacture is roughly computed at £900,000. Considering the prejudices that had to be overcome in introducing cycles, and the risks that had to be incurred in embarking capital in a manufacture which few thought at the time was dependent upon anything more than a passing fancy, it must be allowed that a wonderful advance has been made in so short a period.

Performances.— A few of the most remarkable performances by which public notice has been attracted to cycles are here recorded, being given in tabulated form for convenience of comparison

See Page 2 Table

From these performances it appears that, whether in short or long races, a bicycle has the advantage in speed over a tricycle to the extent of 2 to 2 miles per hour; while as the length of the race increases from 1 mile up to 100 miles, the mean speed of both machines alike falls off by the amount of 5 to 5.5 miles per hour.

Classification.— The large variety of cycles may be classified as follows:—

Bicycles.

- 1. Bicycles of the ordinary type.

- 2. Safety bicycles, which may be subdivided into

- a. Dwarf bicycles with geared rotary action.

- b. Dwarf bicycles with lever action.

- c. Safety bicycles with steering wheel in front.

- 3. Tandem bicycles.

- 4. Otto bicycle.

Tricycles.

- 1. Single Drivers, which may be subdivided into

- a. Rear steerers.

- b. Coventry Rotary, side steerer.

- c. Double front steerers

- 2. Double Drivers, which may be subdivided into

- a. Those driving by clutch action.

- b. Those driving by differential gear.

- 3. Humber tricycle.

- 4. Hand-power tricycles.

- 5. Sociables.

- 6. Tandems.

- 7. Carriers.

All these tricycles may be again subdivided as driven by "rotary" or by "lever" action, like the bicycles.

Any particular make of machine mentioned in this paper will be referred to only in a typical sense, without implying that it is better than others, the author's position being a neutral one, as he is not connected with any firm engaged in the manufacture of cycles.

Ordinary Bicycles.— The ordinary type of bicycle illustrated by Fig. 1 is so familiar that it need not be referred to at any length, as the special details of its construction will be dealt with later on. As regards its balance, anything supported on only two points is not stable, and will fall to one side or the other. In a bicycle one of the two points, which are the two wheels, is capable of being turned, constituting when in motion an act of recovery, because by turning the wheel to the side towards which the machine is falling the balance is recovered; and equilibrium is maintained by continually turning the wheel towards one side or the other. As the rider is seated only a little behind the centre of the shriving wheel, he is able by means of his feet alone to control the steering and so to maintain his balance, the cranks forming levers by which he is able to turn the driving wheel as required to either side. Owing to this action he must, when exerting any power, pull at the handle-bar with his arms alternately on the one side and on the other, in order to counteract the thrust of his feet on the cranks; otherwise the machine would be turning first to one side and then to the other. It is this combined action which renders the riding of a bicycle so difficult to learn. Theoretically it is impossible to ride a bicycle in a perfectly straight has except at a very high speed, and then only for a short distance when no power is being exerted to drive it. As soon as the freedom to deviate from the straight line is removed, the balance is destroyed, and the rider is compelled to dismount; for instance, if the wheels get into the groove of a tram rail, or if the steering head becomes locked, in either case the bicycle is prevented from being steered, and can no longer be ridden.

Weight.— The weight of the ordinary roadster bicycle varies from as many lbs. as there are incises in the diameter of the driving wheel, down to from 15 to 20 lbs. less than the weight corresponding with 1 lb. per inch of diameter. The racer illustrated in Fig. 2 weighs from 18 lbs. to 25 lbs. according to the size of the driving wheel. The weight of a 54-inch bicycle is divided amongst its several parts in the following approximate proportions:—

- Driving wheel with cranks - 40 per cent.

- Steering wheel – 78 per cent.

- Front fork with head, handle-bar, and brake fittings - 25 per cent.

- Backbone with spring – 17.5 per cent.

- Saddle and pedals – 10 per cent.

- Total: 100 per cent.

Vibration.— One of the chief improvements has been the introduction of rubber cushions in various parts of the machine, for absorbing and lessening the vibration which is the one great discomfort of cycle riding. Fig. 3 shows the addition of rubber cushions round the bearings of the front wheel, and Fig. 4 round those of the back wheel. Fig. 5 shows the suspension of the spring on rubber buffers. Fig. 6 shows the method of severing the metallic contact between the handle-bar and the head which carries it. By these means Mr. Salamon, the inventor of this plan, has brought his "Matchless" bicycle to a high state of perfection; and the tricycle has also been similarly improved, with the same beneficial results.

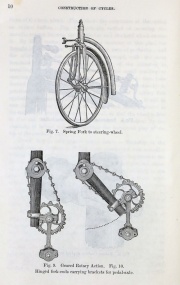

As a large proportion of the vibration in travelling over a rough road arises from the small trailing or steering wheel, various arrangements have from time to time been devised for absorbing it. One which acts most beneficially in practice is illustrated in Fig. 7, and consists of a spring fork applied to the steering wheel of a front-steering tricycle. It will be seen that the wheel is carried in an auxiliary fork which is pivoted to the ends of the prongs of the ordinary fork, so that the wheel is free to rise and fall within certain limits, which are defined by the elasticity of helical springs controlling the horizontal play of the top of the auxiliary fork.

Dwarf Bicycles with geared rotary action.— Machines of the second class, as illustrated in Fig. 8, are constructed with a smaller driving wheel; and the power, instead of being applied direct to the driving wheel, is transmitted to it through a pair of chains and chain-wheels from a divided pedal-axle placed below and slightly in the rear of the driving-wheel axle, so that the rider's feet are much nearer the ground. The use of chains and chain-wheels to connect the pedal-axle with the driving wheel permits the latter to be geared up, so as to be equal in speed to any desired size of driving wheel, independent of the length of the rider's legs. To this is to be attributed in the author's opinion the efficiency of this type of machine; for as its weight is not less than that of an ordinary ungeared machine, while the internal friction is of necessity greater, some extraneous reason must be assigned to account for its ease of propulsion and consequent speed. One such reason may be the fact that the low speed of pedalling does not produce so much exhaustion as is experienced from a more rapid movement of the legs. Within certain limits a machine of this class may be adjusted to suit riders of any height, by raising or lowering the pedal-axle brackets and shortening or lengthening the chains. A simple method of effecting this adjustment without altering the length of the chains is illustrated in Figs. 9 and 10.

The lower ends of the fork carrying the pedal-axle brackets are hinged at the centre of the driving wheel, so that they may be turned thereon for adjusting the height of the pedal-axle from the ground.

Dwarf Bicycles with lever action.— Of dwarf bicycles propelled by a lever action the "Facile," illustrated in Fig. 11, is a prominent example. The fork of the front wheel is extended below the driving axle, and on the ends of the prongs are pivoted two pedal-levers, worked at their free ends by the feet. The levers work the cranks through connecting-rods so arranged as to increase the effective leverage. The action of the feet is simply reciprocating, the path of the pedals being only an arc of a circle of which the radius is equal to the length of the lever. There is here no multiplication of the speed by gearing, inasmuch as the pedal levers act direct on the driving wheel through the connecting-rods and cranks, and the reciprocations of the feet are accordingly equal in number to the revolutions of the driving wheel.

In another type of lever-action machine, the "’Xtraordinary," illustrated in Fig. 12, the pedal levers are suspended from short links pivoted on the prongs of the driving-wheel fork near their junction at the head; and the pedal levers are themselves connected direct to the cranks, being afterwards curved backwards to bring their free extremities well under the rider's feet. Here the path of the pedals is an ellipse, being a mean between the complete circle of the purely rotary machines, and the circular arc of the simply reciprocating. The front fork is here made to rake backwards, so as to keep the centre of gravity well behind the axle of the driving wheel; and owing to the consequent safe position of the rider a larger driving wheel can be used without seriously curtailing the safety of the machine.

Safety Bicycles with steering wheel in front.— Another safety bicycle, illustrated in Fig. 13, has the steering wheel placed in front of the driver. The rider sits as much over the driving wheel as possible, and drives a pedal crank-axle, which is mounted immediately in front of the driving wheel and is geared to it by a chain and pair of chain-wheels. A through pedal-axle can here be used, and consequently only a single driving-chain is necessary. But by using a divided pedal-axle and two chains, as shown in Fig. 14, the rider can sit more directly over the driving wheel, and can thus take a great deal of the weight off the steering wheel, which enables the machine to run easier and to be more easily steered.

The saddle and the pedal-axle are mounted on an independent frame, pivoted on the axle of the driving wheel and free to swing either backwards or forwards; and a locking detent attached to the main frame engages with a notched sector fixed to the top of the swing frame, and locks the swing frame to the main frame. By this arrangement the rider is enabled to shift his position so as to keep his weight directly over the driving wheel on any gradient. As the swing frame is pivoted at the centre of the driving wheel, the length of the chains is constant in every position. A similar arrangement is also fitted to tricycles, as will hereafter be described. As the rider on this type of machine is seated upon the frame on which the pedal crank-axle is mounted, the power exerted on the pedals has no effect on the steering; and therefore this bicycle cannot be steered by the feet, as the ordinary bicycle can. The steering wheel is controlled by a transverse handle-bar, connected to the steering-wheel fork either directly, as illustrated in Fig. 13, or indirectly by means of levers and connecting-rods, as illustrated in Fig. 15. A modified form of this bicycle is illustrated in Fig. 15n, in which the steering wheel is made larger than the driving wheel; this renders the steering less sensitive, though it adds materially to the weight of the machine and certainly does not improve its appearance.

Owing to the position of the steering wheel in front of the driving wheel, the steering is rather sensitive and consequently erratic, and various means have been contrived to keep the front wheel running in a straight line; but as any such devices tend to destroy the sensitiveness necessary for maintaining a balance, they have not always had the desired effect. When this difficulty is overcome, this type of bicycle will excel its competitors, as it is almost absolutely safe, and moreover is almost entirely free from vibration, owing to the position of the rider being nearly midway in the length of the wheel-base, which causes the machine to have a gentle rocking action over rough roads. By the arrangement illustrated in Diagram 16 the difficulty of controlling the steering has been overcome by the author with a certain measure of success, by connecting the pedal crank-axle with the transverse handle-bar, so that the feet turn with the handles, thus permitting of the steering being controlled by the feet, as in an ordinary bicycle. The rider is thereby enabled both to steady the machine and to balance himself with his feet as well as with his hands, and also to steer by means of his feet alone when desired. The pedal crank-axle A is mounted in a bracket B fixed to the vertical rod C, which carries the transverse steering handle-bar, and which is mounted in a suitable bearing D fixed to the frame of the machine. On the centre of the axle is formed a ball or sphere, on which is mounted a duplex chain-wheel E; a pin F passes through the wheel and the axle, and forms the driving connection between them. In order that the axle may swivel in a horizontal plane during any position of the chain-wheel, a slot is cut through the ball to allow of the free swivelling of the driving pin. Instead of using a duplex chain-wheel, a single one overhung may be used, with an internal bearing to take the pull of the driving chain; but the duplex method illustrated is preferable on account of its simplicity. The two chains then divide the work between them, and balance each other in the direction of their pull. Two small rollers mounted on the bearing D bear against the rim of the chain-wheel, and take the upward component of the pull. This steering arrangement is also applicable to central- driving tricycles steered with a transverse handle-bar, in which ease the chain-wheel is mounted directly central with the ball on the pedal-axle, and therefore requires only a bearing on each side to steady it.

Tandem Bicycles.— Of these there are as yet but two makes, both of which have been originated by Mr. Rucker. The earlier one, illustrated in Fig. 17, is constructed of two ordinary bicycle driving-wheels complete in their forks; and the forks are then connected by a backbone, which contains in its length a swivel or axial joint. Each rider drives his own wheel, sitting just behind its centre; and each steers independently of the other for balancing himself. The axial joint in the backbone, and the joints formed by the heads of the forks and the bearings of the wheels, together make a perfect universal joint between the two wheels. Within certain limits the rear rider has of course to follow in the track of the front wheel; otherwise the heads of the two forks become locked and a dismount is rendered necessary. Although this machine is very fast, lighter than two ordinary bicycles, and almost entirely free from vibration, there is an element of danger about it that militates against its general use, inasmuch as it demands to a certain extent a unity of thought and action on the part of both riders.

From a tricycle designed as a modified form of this bicycle, and illustrated in Fig. 17e, very satisfactory results have been obtained by the author. Instead of having two bicycle driving- wheels, it is constructed with one bicycle driving-wheel in front and a pair of 'driving wheels behind belonging to a "Humber " tricycle, which are connected with the front wheel by a similar backbone. As the rear rider does not require to balance himself, he has nothing else to attend to than to follow the front rider; consequently the greatest element of danger is removed. This machine would probably give better results if the direct-action bicycle wheel were replaced by a small wheel with a geared rotary action. Its efficiency is doubtless due to the equal distribution of the wheel load, and to the fact that all the wheels are drivers.

The later tandem bicycle, illustrated in Fig. 18, eclipses the earlier, and bids fair to prove the fastest yet produced. It is constructed on the lines of a dwarf geared bicycle. The scat for the front rider is mounted immediately over the centre of the driving wheel; and that for the rear rider, who steers the machine, is nearly midway between the two wheels. Divided pedal-axles are mounted fore and aft of the driving wheel, with which each is connected by a chain and chain-wheels. The front rider being seated on the fork carrying the driving wheel, which is also the steering wheel, has no control over the steering, which is therefore left entirely to the rear rider. The weight of this bicycle is only 55 lbs., and it is therefore the lightest machine yet made to carry two riders.

Otto Bicycle.— This peculiar machine, illustrated in Fig. 19, and due to the brother of the inventor of the gas engine known by the same name, is almost more nearly allied to a tricycle than to the bicycle proper; but as it has only two wheels, and consequently requires the balance to be still maintained by the rider, it is rightly called a bicycle. The wheels are of equal size, and are here mounted loose on the same axle, parallel to each other, and both of them are drivers. The rider sits between them, and works a continuous pedal crank-axle, the position of which, when he is seated, is below and slightly in front of the axle carrying the driving wheels. The crank-axle is connected with the driving wheels by endless steel bands, passing round plain pulleys on the ends of the crank-axle and on each wheel. The bands are kept taut by tightening springs, and the machine is steered by slacking one or other of them, which causes the corresponding driving wheel to lose motion, and therefore the other wheel runs round it. If a very sharp turn has to be made suddenly, a brake is applied to one wheel at the same time that its driving band is slackened, which causes the machine to turn round in a circle upon that wheel as the centre. This machine having no small wheel fore or aft, the rider, while steady sideways, has to balance himself in the direction of his motion, which he is enabled to do through the medium of the pedal crank-axle; by pressing on the forward pedal, if he is falling forwards, he throws his weight backwards; and by pressing on the rear pedal, if he is falling backwards, he throws his weight forwards. To preserve him from actually capsizing backwards, a safety tail projects behind the seat, carrying a small roller at its extremity, which will bear upon the ground whenever the seat is tipped too far back. Among the many beautiful features presented by this machine the best seem to be,— firstly, its balance, whereby the rider is always in the best position to utilise his strength and weight, notwithstanding the varying gradients; secondly, the nicety with which it can be steered; thirdly, its tendency to run in a straight line without any effort on the part of the rider; fourthly, its freedom from vibration; and fifthly, the circumstance that it makes only two tracks.

TRICYCLES.

The tricycle presents far greater difficulties than the bicycle. It is necessary that any one of its three wheels shall be free to move in its own direction, independent of the united action of the other two. For running in a straight line, all three wheels must be parallel; whilst for running round a curve, one or more of the wheels must be turned until the centre lines of the axles intersect in plan, their point of intersection being the centre of the curve round which the machine will thou run; therefore the more acute the angle of intersection, the greater will be the radius of the curve; and inversely, the more obtuse the angle, the sharper will be the curve. Besides being independent in direction of running, each wheel must also be capable of rev 1 sing at a greater or less speed than the others. It is also essential that the greater part of the rider's weight shall be on the driving wheel or wheels, and that only enough shall be on the steering wheels or wheel for ensuring their proper action. Owing to the variety of ways in which these principles can be carried out practically, it is easy to account for the variety of tricycles constructed.

Single-driving Tricycle.— The simplest form of tricycle is obviously that with only one driving wheel, either or both of the others being used for steering. An early type of single-driver, now practically obsolete, had two large wheels mounted opposite and parallel to each other, one of which was driven, and the other was allowed to run free; the third or steering wheel was placed centrally in the rear.

Coventry Rotary Tricycle.— Another single-driver, illustrated in Fig. 20, and known as the "Coventry Rotary," has the large driving-wheel on one side, and two small steering wheels on the opposite side, placed respectively fore and aft of the driver, and arranged to turn together but in contrary directions. The double steering, fore and aft of the driving wheel, overcomes the tendency of the machine to run in a curve in consequence of the single driving-wheel on one side. This was one of the first tricycles introduced, and has stood the test of competition, being at the present time one of the most popular. Its chief features are that it is simple in construction, makes only two tracks when running, and is narrow in width. Its narrowness, although rendering it somewhat unstable in running round a curve at a high speed, allows of its passing through a doorway of ordinary width. This machine was the invention of the late Mr. James Starley, who has been justly styled "the father of the cycle industry," and to whose memory a monument has recently been erected on a public site in Coventry.

Front-steering Tricycle.— The third and last kind of single-driver, as illustrated in Fig. 21, has the driving wheel placed centrally in the rear of two steering wheels, which are mounted parallel and opposite to each other. The defect of this arrangement is that the weight of the rider is too equally distributed over the three wheels, instead of coming more upon the driver than upon the other two.

Double-driving Tricycles.— In these the two driving wheels are always placed parallel and opposite to each other, with the steering wheel in front or behind and generally central; though in some cases it is placed in line with one of the driving wheels, no that the machine then makes only two tracks, as illustrated in Fig. 21A. There are two methods of double driving:— firstly by clutch action, and secondly by differential or balance gear.

Double driving by clutch action.— In this plan the two driving wheels, or the chain-wheels driving them, are locked to their axle while the tricycle is being driven forwards in a straight line; but in running round a curve the outer wheel over-runs the clutch, and the inner wheel alone drives. As only one wheel drives when the machine deviates from its straight path, the clutches in order to drive satisfactorily must be instantaneous in their action, in order that both driving wheels may be locked to their respective chain-wheels or axle immediately on the machine again running in a straight line. Of the many various clutches that have as yet been devised, none have produced better results than that known as the Bourdon clutch, which is illustrated in Diagram 22 as applied to the pedal crank-axle. It consists of a disc D, fixed on the crank-axle A, and having its circumference cut away so as to form three or more inclined planes. A cylindrical box B, forming the boss of the chain-wheel C, encircles the driving disc D; and in the recesses of the inclined planes are placed small rollers R R, which jam between the disc D and the box B, and so lock the two together as long as the axle is driving the wheel. Whenever the wheel has freed itself by over-running the axle, it will be seen that in every position there will always be at least one of the rollers ready to lock the wheel to the axle again instantaneously as soon as ever its speed falls back to that of the axle.

A clutch-driven machine of course cannot be driven backwards without some extra gearing; nor can it be stopped by back pedalling, and in consequence the burden of checking the speed is thrown entirely on the brake. As a set-off against this disadvantage, the pedals are free to remain stationary while the machine is continuing to run forwards: au advantage which certainly economises the expenditure of power, inasmuch as the feet can rest motionless on the pedals whenever the gradient of the road will allow the machine to run of itself. Various attempts have been made to construct a clutch that will drive automatically in both directions, but all have proved unsuccessful in consequence of not being instantaneous in action; and it appears impracticable to make a clutch which shall drive in both directions without allowing a small amount of back-lash between the forward and the backward grip. If a clutch could be made to act instantaneously in both directions, it would form a better double-driving gear than the differential or balance gear which at the present time is the best plan of double driving for general application. Having been asked some time ago to devise a means of making a clutch drive in both directions, the author has taken the Bourdon as a perfect clutch for driving in one direction; and from the experiments he has thus far made he hopes to succeed in the object aimed at.

Double driving by differential or balance gear.— This other mode of double driving, so called because the power is divided or "balanced" between the two driving wheels, consists of an epicyclic train in which the two primary wheels are each connected directly or indirectly with one of the driving wheels of the tricycle, while they are also connected with each other through an intermediate loose train of mechanism carried by an arm. The simplest form of differential gear is that shown in Diagram 23, and invented by the late Mr. James Starley, who first applied it to tricycles. It somewhat resembles an ordinary reversing train, being constructed of three bevel wheels one of the two facing wheels A is fixed to the hub of one of the driving wheels, which runs loose on the axle; and the other is fixed on the driving axle, on the end of which the other driving wheel is fixed. Between the two facing wheels is mounted the chain-wheel C, which runs loose on the axle, and carries loose on a radial axis the small bevel pinion P gearing permanently with the two facing wheels. So long as the tricycle is running in a straight line, both of the driving wheels are driven equally by the chain-wheel C, the two facing wheels being simply dragged round by the intermediate pinion P, which at that time is not rotating round its own axis. But when the tricycle is steered in a curve, the inner driving wheel revolves at a slower rate than the chain-wheel; and consequently the outer driving wheel is driven through the bevel gear at a correspondingly higher speed, in whichever direction the machine is running, whether forwards or backwards.

There are many various forms of differential gear, some of which are exhibited; as the result produced by each is identical, it is not necessary to describe all of them in detail. But there is one which from its construction is specially suitable for central-geared machines, and is illustrated in Fig. 24. The driving axle A A, on the ends of which are fixed the driving wheels, is divided in the middle of its length; and the two half lengths are united by a coupling box E, which has a long tubular neck B at each end, running loose upon the axle, and carried in the bearings of the machine. On one neck is fixed the chain-wheel F, by which the coupling box E is driven. Inside the coupling box are two short parallel shafts C, inclined at 30° to the driving axle, and geared together by equal pinions D; one end of each shaft is carried in a socket in the coupling box, and the other end is connected by a universal joint to the opposite half of the driving axle. Another form of differential gear has been constructed to work through the crank-axle, for use on open-fronted rear-steering machines; but it is not a practical success, owing to the intricacy and extra weight entailed.

In a clutch-driving machine it will be seen that the same amount of power is always applied to each of the driving wheels, so long as the machine is running in a straight line, and that no extraneous resistance to either wheel will deprive it of its half share of the total power. In a machine driven by differential gear each wheel receives its due proportion of power: thus, in running in a straight line, each wheel receives half the total power, and in running round a curve each receives the proportion due to its relative speed. This so far is as it should be; but if, while the machine is running in a straight line, one wheel encounters greater resistance from the ground than the other, this wheel ought in a perfect double-driving machine to receive a larger share of the power. With none of the existing forms of differential gear however is this result attained. The action of the two kinds of gear can be practically tested by taking two machines, one driven by clutch action and the other by differential gear, and disconnecting the steering wheel so that it may trail and run free. If while these machines are driven straight forwards an obstruction be placed in the path of one of the driving wheels of each, the clutch-driven machine, if its impetus be sufficient, will pass over it without deviating from the straight line; but the differential- geared machine will swerve round to the side on which the obstacle occurs, and will probably fail to pass over it. In differential-geared machines therefore it is important to have sufficient weight on the steering wheel for ensuring its controlling the action of the differential gear. Fig. 25 illustrates a rear-steering tricycle driven by clutch action; Fig. 26 a rear steerer driven by differential gear; Fig. 27 a front steerer driven by differential gear.

Humber Tricycle.— Among the tricycles driven by differential gear, the one known by this name after its inventor is widely different from all others, as illustrated in Fig. 28. The rider sits astride a backbone carrying a trailing wheel, and steers by turning the two driving wheels by means of a transverse handle-bar, as is done in a bicycle. To the dwarf bicycle its appearance bears a considerable resemblance, except that on a bicycle the rider sits over the single driving-wheel, whereas on the Humber tricycle he sits between the two driving wheels. The efficiency of the differential gear as a means of double driving is specially prominent in this machine, because it allows the driving wheels to be used as steering wheels without in any way affecting its double-driving properties.

In Fig. 29 is illustrated a modification of the Humber tricycle, which is steered by a pair of upright spade-handles, instead of by a transverse handle-bar. The backbone is connected with the frame carrying the driving wheels by an arrangement of friction discs, instead of by the usual head, no that the sensitiveness of the steering may be varied to suit individual likings. This machine is further designed so as to be easily taken to pieces for convenience of transport.

As already described in regard to bicycles, there are two methods of driving a tricycle: firstly, by rotary action, in which case the power is applied either directly to a cranked axle carrying the driving wheels, or to a cranked pedal-axle connected with the driving-wheel axle through an endless chain or other means; and secondly, by lever action, where the power is applied by reciprocating pedal-levers, from which the motion is communicated to the driving-wheel axle through cranks and coupling-rods or otherwise. The lever action lends itself most aptly to obtain varying power; but in speed the rotary action is superior. The reason would seem to be that in the lever action the direction of force is changed so suddenly that in rapid pedalling a certain amount of back pressure is unavoidable.

Omnicycle.— One of the most successful lever machines is the Omnicycle, illustrated in Fig. 30. Its success is due to the variable- power gear with which it is fitted. The pedal levers arc connected by bands to two expanding segments, which are each connected to the driving axle by clutches, and to each other by a reversing apparatus, so that the forward movement of the one produces the back ward movement of the other, and thus the descending pedal raises the other ready for the next stroke. The segments are constructed so that they can be expanded or contracted, so as to give greater or less leverage, as shown in Figs. 31, 32, and 33, in which the segments are represented at their extreme and mean radii.

Direct-action Tricycle.— Of rotary tricycles the simplest form is that illustrated in Fig. 34, with the two driving wheels mounted on the ends of a cranked axle and connected to it by clutches, the rider driving the axle direct. This arrangement simplifies the construction, and reduces the working parts; but it has the one insuperable objection of instability, owing to the high position of the centre of gravity. In another tricycle, Fig. 35, swinging pedals are hung from the cranked axle, whereby the centre of gravity is slightly lowered and the machine rendered somewhat more stable.

Transmission of Driving Power.— Reverting to the ordinary type of tricycle, in which the power is applied to a cranked pedal-axle and thence transmitted to the driving axle, there are three principal methods at present in use for its transmission firstly, by chains or bands; secondly, by gear wheels; thirdly, by cranks and coupling-rods. Many other plans have also been tried at various times.

Driving Chains.— These are the most popular means of transmitting the driving power, as they offer the greatest facilities for gearing the driving wheels up or down. Samples of the various chains in use are exhibited; but the only two calling for any special notice are the Morgan and the Abingdon. The Morgan chain, shown in Fig. 36, is composed of rectangular links made of round steel wire, which alternate with hollow steel rollers. The chief feature of the Abingdon chain, shown in Fig. 37, is that, with the exception of the pins which rivet the links together, all the parts are of one uniform pattern; and the side plates of the links being so constructed that the ends break joint with one another, the chain can be shortened or lengthened by only one link at a time, whereas all other chains require two links for alteration in length.

Driving Bands.— Steel bands, either plain or perforated, have been used with some success. The Otto bicycle is the only machine on which plain bands are used for driving, a tension being exerted between the bearings of the two axles so as to keep the bands taut. Perforated bands have also been used, with toothed pulleys. But the power expended in the continuous flexure of bands in passing over their pulleys outweighs any other advantages they may have.

Gear Wheels.— In this mode of driving, an intermediate wheel gears with those on each axle; but as the wear cannot be taken up without destroying the pitch-line of the teeth, the plan does not prove satisfactory in practice. The teeth of the intermediate wheel are sometimes fitted with rollers to lessen the friction, as shown in Fig. 38. The two axles have also been connected by a vertical shaft, carrying at each end a bevel wheel, which gears with other bevel wheels on the respective axles, as shown in Fig. 39. This arrangement is open to the same objection as the preceding one.

Coupling-Rods.— Cranks and coupling-rods are used on some tricycles, as illustrated in Fig. 40. With the exception that they will not permit of the driving wheels being geared up or down, and that they cannot be used with a differential gear, they give very good results.

The latest method of communicating motion is a combination of eccentrics and steel bands, invented by Mr. Boys. Eccentrics being equivalent to cranks, two equal eccentrics are fixed on each axle with their throws opposite; and an endless steel band embracing each pair acts as a coupling-rod between them.

Variable-Speed Gear.— Various arrangements have been introduced for varying the speed of the driving wheels in relation to that of the pedal crank-axle, whilst the tricycle is in motion, so as to obtain varying degrees of power for suiting the exigencies of the road. There are the five following methods of doing this.

lst. A set of change-wheels may be thrown in and out of action as desired.

2nd. An epicyclic train may be used, which for one speed is locked together and moves as a single piece, and is set in motion for the other speed. These gears are constructed so as to be quiescent at either the higher speed or the lower. In Diagrams 41 and 42 is illustrated a two-speed gear in which the epicyclic train is quiescent at the lower speed and in motion at the higher. On the end of the crank-axle A is mounted a loose chain-wheel C, having a ring of internal teeth. Fixed on the axle is a boss B with four arms, on each of which is centered a small live pinion P. The four pinions gear with the internal teeth in the chain-wheel C, and also with a central pinion E mounted loose on the outside of the four-armed boss B. Pivoted to the boss of the central pinion E is a fork F, of which the spring handle engages in any one of a ring of notches cut in the edge of the chain-wheel, and thereby locks the pinion to the chain-wheel C: so that, when power is transmitted from the axle through the four arms, the whole train moves together as if it were a single piece, and the tricycle is driven at the normal speed to which it is geared by the chain-wheels. When it is desired to increase the speed, a wedge-faced arm conveniently pivoted on the frame of the tricycle is dropped, so as to throw the spring handle of the fork F out of its notch and hold it stationary; the central pinion E being thereby prevented from revolving, the chain-wheel C will be driven at a higher speed than the crank-axle, owing to the revolution of the four live pinions P round the stationary central pinion E.

In Figs. 43 to 46 is illustrated a converse arrangement of two- speed gear, known as the crypto-dynamic or " crypt° " gear, which is quiescent at the higher speed and in motion at the lower. In Fig. 43 is shown an outside view of the gear as closed up complete. In Fig. 44 is seen the interior of the gear, when the internally toothed driving wheel is removed, which is shown separately in Fig. 45. In Fig. 46 is shown a longitudinal section of the gear. The internally toothed wheel is keyed on the axle, and is therefore the driver. The four intermediate live pinions are mounted on the chain-wheel, and the central loose pinion is fitted with a clutch, so that it may either be locked to the chain-wheel, or be held stationary. In the former case, the whole train revolves as one piece, and the tricycle is driven at its normal speed; but when the central pinion is held stationary, the chain-wheel runs slower than the axle, owing to the speed lost through the live pinions revolving round the stationary central pinion.

3rd. A third plan is to use two sets of chain-wheels and chains, one gearing for power and the other for speed, either of which can be connected or disconnected at pleasure.

4th. Expanding chain-wheels can be used. Generally one only is employed, and an idle pulley is provided for taking up the slack of the chain when the wheel is at its smallest diameter. A specimen of an expanding chain-wheel is exhibited, in which the pitch of the teeth is never altered.

5th. Another method of obtaining increased power is to use cranks with a variable throw. The simplest form is illustrated in Diagram 47, which shows a left-hand crank, the right-hand one being of a similar construction with the locking parts reversed. Each crank is quite independent of the other. On each end of the axle A is fixed an eccentric E, their throws being opposite to each other. The crank C is formed with a strap S passing round the eccentric, and is provided with a pawl D, which engages with either one of two ratchet-teeth cut in the circumference of the eccentric, and locks the crank to the eccentric at one or other of the two throws, so that motion may be communicated to the axle when the crank is moved forwards. A flat spring F produces frictional resistance between the eccentric and the strap, sufficient for lifting the rising pedal.

In order that the rider may be enabled to exert a retarding force through the crank while it is rising, for the purpose of checking the speed of the machine or of driving it backwards, a gravitating bolt B, sliding loose in a diametrical direction across the eccentric, engages with a tooth cut on the inner edge of the crank strap, thus locking the eccentric to the strap against any backward pressure. The action of this gravitating bolt is such that it locks the crank to the eccentric when the pedal is rising, so that back pressure may then be exerted; and unlocks it when the pedal is falling. Consequently if the crank be prevented from rising when it reaches the bottom, in which position the gravitating bolt is just on the point of reversing itself, the throw of the crank will automatically alter itself, and will lock itself in the other position, providing there is sufficient momentum in the machine to carry it forwards through half a revolution. For inasmuch as each crank is quite independent of the other, and can be altered only when in one position - namely when it reaches the bottom of its stroke - each crank requires half a revolution of the axle for effecting its alteration. Thus if the right-hand crank be held stationary at the bottom of its stroke, its throw will be altered during the next half-revolution of the axle, during which the left-hand crank will also have come down to the bottom of its stroke, where it will then be held stationary during the following half-revolution for altering its throw, while the right- hand crank will be rising to the top of its stroke; and during this latter half-revolution neither crank will be exerting any forward driving power. On its completion the two cranks will then be on opposite centres again, each with its altered throw.

Position of Rider.— In each different make of tricycle there is a certain position for the rider's seat, in respect both to the axle of the driving wheel and also to the pedal crank-axle, which when the machine is travelling along a level road will permit of the rider exerting his power to the best advantage. But on a gradient this position changes, and consequently the rider's position should also be altered. In ascending a hill, the position of the rider requires to be moved forward; which accounts for the strained attitude that some riders are obliged then to assume. The best position for the seat on a front-steering tricycle is generally 1.5 inches in front of the driving axle and 7 inches behind the pedal-axle, this axle being therefore 8.5 inches in front of the driving axle.

Various arrangements have been devised for enabling the rider to alter his position according to the gradient. The most perfect is the swing frame, as applied to the Devon tricycle by Mr. F. Warner Jones, which is similar to that applied to the dwarf bicycle illustrated in Fig. 14. It consists in mounting the saddle and the pedal crank-axle on a swinging frame, pivoted inside the main frame, so that it may swing backwards and forwards, and thereby place the rider in the best position for exerting his power. The swinging frame is provided with a locking apparatus for fixing it in any desired position relative to the main frame. Fig. 48 illustrates a tricycle fitted with a swing frame. Fig. 49 shows the position of a rider in ascending a hill on a machine without a swing frame; and Fig. 50 shows his position on one with a swing frame.

A modification of this arrangement has been introduced by Mr. J. Alfred Griffiths, in which the swing frame is always on the balance, so that the rider's position corrects itself automatically within certain limits determined by a spring. As this subject will be dealt with by Mr. Griffiths in his own paper, it need not be anticipated here by further description.

Another method of correcting the position for varying gradients is to mount the seat or saddle in such a manner that it may be moved backwards or forwards within certain limits without the rider having to dismount. In Fig. 51 is illustrated such an arrangement, in which the saddle is mounted on a sliding frame, so that it can be shifted forwards or backwards by a hand-lever acting through an arm and link.

Hand-Power Tricycles.— Various machines have from time to time been introduced in which the driving power is exerted by the arms, instead of by the legs; but as the power of the legs is normally greater than that of the arms, these machines cannot compete with the usual cycles, and are intended only to meet certain special requirements. Only two machines call for particular notice: the Velociman and the Oarsman. The Velociman, illustrated in Fig. 52, is specially designed for those who have lost the use of their legs, and is constructed with a pair of driving wheels on a differential-geared axle, which is connected by an endless chain and chain- wheels to a cranked lay-shaft worked by the hand-levers. A rear steering wheel is controlled by a pad behind the seat, against which the rider leans back. The Oarsman, illustrated in Fig. 53, is driven by an action similar to rowing. It has two driving wheels and a front steering wheel. It is driven by clutches on the driving wheels, which are actuated by endless cords passing round the clutch drums and also round small pulleys mounted on the front of the machine. A cross bar connects the two cords, and the machine is propelled by pulling the bar, which at the end of each backward stroke is returned to its forward position by springs. The rider sits on a sliding seat mounted on the frame, which is nearly horizontal.

Sociable Tricycles.— Of tricycles to carry two riders there are two kinds, the "Sociable" and the "Tandem." In the former, the riders sit side by side; in the latter, one behind the other. The Sociable is merely an enlargement of the single form of tricycle, with some parts in duplicate. Some Sociables are capable of being converted into single machines, that illustrated in Fig. 54 being the simplest. In its single form this is a "Coventry Rotary," illustrated in Fig. 20, the part that is attached to make the double machine being simply a duplicate of the single half, without the two steering wheels and steering gear and the tube that carries them, as illustrated. in Fig. 55, which shows the single machine and the detached half.

As the machine in its double form has four wheels on the ground, the added half is connected to the single machine by a hinge joint, as illustrated in Fig. 56, so that it may accommodate itself to the inequalities of the road. Figs. 57 and 58 illustrate a convertible Sociable of the ordinary front-steering type, the former showing it in its double form, and the latter in its single form, with the detached part by the side of it.

Tandem Tricycles.— In these there is more scope for variety, and the different machines may be classed as follows:—

1st. The ordinary front or rear-steering tricycle, illustrated in Fig. 59, in which the wheel base is extended, so that the riders may be seated fore and aft of the differential-geared driving-axle without destroying the balance of the machine.

2nd. The Humber Tandem., Fig. 60, in which the extra rider is seated in front of the driving axle, but as nearly over it as possible, and communicates motion to it from a pedal crank-axle in a similar manner to the rear rider, who is seated further back than in the single machine, so as to counterbalance the extra weight in front.

3rd. The tandem tricycle in which an auxiliary trailing frame is fixed in the rear of an ordinary front-steering tricycle, as illustrated in Fig. 61, so that there may be plenty of room between the two riders. In order that the trailing frame may rise and fall with the inequalities of the road, and may follow properly when the machine is running round a curve, it is necessary to have both a transverse and a vertical joint between the two frames. In Fig. 62 is illustrated an auxiliary frame suitable for attaching to any front-steering tricycle so as to convert it into a tandem. It is provided with both vertical and transverse joint; and can be the more easily attached and detached because the power is transmitted to its own wheel, instead of to the driving axle of the tricycle to which it is attached.

Carrier Tricycles.— The last kind of tricycle, and the most useful of all, is that for carrying a burden. At the present time there is but one tricycle specially constructed for carrying a passenger, although there are several which are capable of being adapted for the purpose. This is illustrated in Fig. 63, and is known as the "Coventry Chair," being an ordinary Bath chair in which the pair of large wheels are replaced by part of a tricycle frame carrying a pair of driving wheels, with pedal crank-axle, and seat for the driver in the rear. As long ago as 1670 a Bath chair propelled by a rider was described by James Ozanam in his French work, "Recreation in Mathematics and Natural Philosophy." Although the Coventry chair has been introduced only a short time, a large number are in use; and some are plying for hire, though the make seems to be too cumbersome for this use, for which it could hardly have been intended originally. As an instance of what can be done with these chairs, one was propelled from Coventry to London, a distance of 95 miles in 22 hours, with a passenger and 50 lbs. of luggage. Another was propelled from Walsall to Rhyl, a distance of 110 miles in 24.5 hours, with a passenger weighing 10 stone and 60 lbs. of luggage, the driver weighing 14.5, stone.

Of goods carriers there are a large number of makes, but there is nothing in their construction to call for special comment; their success depends chiefly on the load being balanced as much as possible on the driving wheels. In Figs. 64 to 68 are illustrated carriers adapted for various purposes. They are largely used by the post office both for the parcels post, Fig. 64; and for the delivery of letters in rural districts, Fig. 65. They are also largely used by newspaper offices for the distribution of papers, Fig. 66; besides being used in almost every trade for the distribution of goods, Figs. 67 and 68.

Arrangement of Driving Gear.— All tricycles driven by a rotary action from a pedal crank-axle may be again subdivided into four classes:-1st, side driving and side geared; 2nd, side driving and central geared; 3rd, central driving and central geared; 4th, central driving and side geared.

In side-driving tricycles, whether side geared or central geared, the frame is generally of the loop shape illustrated in Fig. 27, being constructed of tubing in the form of a loop, which runs down from the bearing on each end of the driving axle in close proximity to the driving wheels, and carries the ends of the cranked pedal-axle, and then curving across carries the short backbone which projects forwards to carry the front steering wheel. The differential gear in the side-geared tricycles is fitted on one end of the driving axle, close up to one of the wheels, as shown in Diagram 23, &c.; and the gear transmitting motion to it from the pedal crank-axle is mounted outside the loop frame. In the central-geared tricycles the differential gear is constructed in the centre of the driving axle, while the driving gear is still kept at the side of the machine.

In central-driving tricycles, whether central geared or side geared, the frame is usually of a T shape, as illustrated in Fig. 59. The horizontal part, or top of the T, carries the bearings for the driving axle; and the vertical part or stalk, after running down to carry the bracket in which is mounted the short pedal-axle fitted with bicycle-cranks and pedals, is curved up again to carry the steering wheel. The differential gear in the central-geared tricycles is constructed in the centre of the axle, and is therefore in line with the driving gear. In the side-geared tricycles the differential gear is placed close up to one of the driving wheels, whilst the driving gear is kept in the centre. The central-driving and central-geared machine is obviously the most perfect, as equal power can thereby be distributed to both driving wheels. Although in practice no appreciable advantage is gained by central-geared machines over side-geared, yet theoretically the advantage lies with the central-geared, because the internal friction of each half of the gear and its attendant parts is the same; whereas in a side-geared machine the one half of the differential gear which is fixed to the driving axle has the friction of the bearings, while the other half which is fixed to one of the driving wheels has not.

In central-driving tricycles it is most essential for the bearings carrying the driving axle to be no distributed that the bending strain caused by the pull of the driving chain shall not cause the axle to sag. In some central-driving machines the bow-sprit tube that carries the steering wheel is run out level from the horizontal part of the frame; and another tube slopes downwards for carrying the pedal crank-shaft bracket, as illustrated in Fig. 70; this makes a stiffer frame, though it limits the use of the machine to men only. The advantages of the T frame are its simplicity and lightness, and also that it permits the use of adjustable cranks.

Width.— As the width of a tricycle varies between 36 and 39 inches — excepting the Coventry Rotary, which from its special design can be made as narrow as 27 inches — many arrangements have been devised for temporarily reducing the width, so as to enable a machine to pass through an ordinary doorway. Two plans only call for special notice, namely folding frames and telescopic frames; all other devices consist in removing one or both of the driving wheels, or detaching some part of the frame. Folding frames are so constructed and hinged together that by removing one or more pins they may be folded up. Figs. 71 and 72 illustrate a tricycle with a folding frame, Fig. 71 showing it ready for riding, and Fig. 72 folded up. In telescopic frames, which are always used with central gearing, the frame and the axle on one side of the machine are made telescopic, so that by slackening one or two nuts the parts will slide one within the other. Figs. 73 and 74 illustrate a telescopic axle as applied to these machines, which is constructed as follows. A solid axle F carries upon one end the driving wheel which is in connection with the double-driving gear, the bearing of the end of the axle being in the cover of the gear box E; the other end of the axle terminates about 10 inches from the other side of the tricycle, instead of being continued right across the full width as in an ordinary machine. Upon it the outer tubular axle G slides with a key, and carries on its outer end the flanges H H of the hub of the other driving wheel. The tubular axle itself slides within the long tubular neck of the gear box E, and revolves freely within it whenever the tricycle is running round a curve. A loose collar K, sliding outside the tubular axle G, is fixed to it by a set-screw L when drawn out to its full extent, so as to lock it in that position. A stop M is also fixed in the key-way of the solid axle F, against which the key of the tubular axle butts when drawn out fully; and by this means therefore the width of the machine is regulated.

Weight of Tricycle.— In a front-steering tricycle with a loop frame, having 50-inch driving wheels and weighing 80 lbs., the weight is divided amongst its several parts in the following approximate proportions:-

- Driving wheels - 31.2 per cent.

- Steering wheel - 5.0 per cent.

- Frame with steering and brake gear - 27.5 per cent.

- Front fork - 2.5 per cent.

- Pedal crank-axle with pedals and chain-wheel - 13.8 per cent.

- Driving axle with differential gear - 15.0 per cent.

- Seat-support with spring and saddle - 5.0 per cent.

- Total: 100.0 per cent.

Of the component parts of modern cycles the following alone call for special notice:— wheels, bearings, frame, steering gear, brake, and pedals.

Wheels.— It was through the introduction of "suspension" wheels that the first real advance was made in the improvement of cycles, as on that principle of construction the wheels can be made very light, rigid, and strong. They are constructed with either solid or hollow rims, the latter being the lightest and strongest. The ordinary make of wheel has a solid rim and direct radial spokes, which are threaded through holes in the rim and screwed direct into the flanges of the hub, being butt-ended or enlarged in the screwed portion, so that the sectional area of the spoke may not be diminished by cutting the thread. The rims are made out of lengths of steel of crescent-shaped section, which are first passed through a set of rollers to curve them to the desired circle; the meeting ends are then scarfed, pinned together, and brazed. Up to the present time the author is not aware that rims have been rolled weldless out of the solid, though there seems to be no reason why this should not be done. In Fig. 75 is shown a section of a solid rim and plain rubber tyre. Hollow rims are made in three ways:—

1st, as shown in Fig. 76, by being rolled out of a length of solid-drawn steel tube;

2nd, as shown in Fig. 77, by being built up of two or more strips of steel plate, first rolled to the required section and then sweated or brazed together;

3rd, as shown in Fig. 78, by being rolled or drawn out of a single strip of steel plate, the edges of which form a lap joint and are then brazed together.

The rubber tyres are constructed of a round section, with either a plain or a corrugated surface; the latter gives a better hold on the surface of the road, and so prevents the wheel from slipping sideways. The tyres are also made of a combination of hard and soft rubber, the hard forming the wearing surface, and the soft the bedding surface or cushion.

The tyre may be fixed to the rim by various methods, that usually adopted being to cement it in; if properly done, this is in every way satisfactory. Some manufacturers prefer to pass a wire along the centre of the tyre, and screw the two ends together by a right-and-left-handed nut. Various sections of rims have been tried for holding the tyre without any extraneous aid; two of them are illustrated in Figs. 79 and 80, but neither of these has been sufficiently long in use to afford evidence of their respective merits; if however after practical test they fail in their purpose, it would seem likely to be from want of cohesion between the tyre and the rim.

In a direct-spoke wheel a certain amount of windage must take place before the power is transmitted through the spokes to the rim. To obviate this, the spokes are sometimes fixed tangentially to the hub in which case also they are generally made in pairs, each pair being threaded through a hole in the flange of the hub, and the outer or free ends being fixed to the rim by small lock-nuts or nipples. In order that the spokes may run tangentially, it is necessary to twist the wire just at the place where it is bent to form the double spoke; this double twist is rather a crucial test for the spokes during construction, and it is not surprising that they always give way first at that place. The latest method of constructing wheels with spokes tangential to the hub is to use single spokes threaded through transverse holes in the hub, and bent to run of at right-angles to the hole, so as to form a kind of hook, as shown in Fig. 81; the spoke ends are also headed, to prevent them from pulling through the holes, and are secured at the rim by nipples or lock-nuts.

One of the latest innovations in the construction of wheels consists in corrugating the spokes longitudinally throughout their entire length, which gives a certain amount of elasticity to the wheel. At first sight it would seem as if these corrugations would seriously diminish the lateral stability of the wheel; but as far as experience shows, such is not the case. As however wheels so constructed have not been very long in use, it remains to be seen whether they will stand the wear and tear of the road.

Bearings.— The bearings of the wheels are now almost without exception made with anti-friction balls interposed between the moving parts. The most approved kind of ball bearing is that known as the "AEolus," illustrated in Diagrams 82 to 84, which is adjustable concentrically, so that the bearing remains perfectly true after adjustment. On the axle A is fixed a collar C, with a shallow groove of circular section turned all round its circumference, into which are placed the balls B. These are enclosed within a concentric casing, which is formed in two parts, D and G. The part D is fixed to the frame of the machine, and the part G is a gland screwing concentrically into D; the inner surface of each part is coned, so that by simply screwing up the gland G the cones are tightened on the whole set of balls, and the bearing is adjusted concentrically. The gland G is prevented from working loose by a small toothed bracket F, engaging in notches round the edge of the gland.

In another construction of bearing, illustrated in Diagrams 85 to 87, two facing cones GG are screwed from opposite sides into a cylindrical casing D, which is split transversely and provided with lugs on each side of the split, so that it may be tightened up by a screw to grip the cones within it. The bearings of the small wheels, as illustrated in Fig. 87 A, and of the pedals; and also in many cases of the head, are constructed in a similar manner. It has been ascertained from careful experiment by Professor Boys that twelve balls in a bearing lost together only 1/20.8 grain in weight in running 1000 miles, or only 1/250 grain per ball, which is equal to an actual surface wear of only 1/158,000 inch.

Frame.— The frames of both bicycles and tricycles are largely constructed of weldless steel tube. The frame of a bicycle consists of two parts, the front fork and the backbone: both of which are made of weldless steel tube. For the front fork, the tube is drawn and tapered into an oval section, so as to give the greatest possible strength to resist the torsional strain produced when the rider pulls at the steering handles; the backbone is left of circular section, and is also tapered towards the back fork, to which it is brazed. The back fork is made out of a blank of sheet steel, bent and blocked into shape, the sides being of a half-round or crescent section. In some machines the back fork is constructed out of a prolongation of the backbone, which is first split up for some distance, and then blocked out into shape.

In the frames of tricycles the tubing is usually left of circular section, and varies in size from 1 to 1.25 inch diameter, and in thickness from 16 to 13 B.W.G. or 0.065 to 0.095 inch, according to the size of the machine and the weight it is intended to carry. Owing to the shape of the frames of tricycles, many solid parts are required; and these are chiefly made in wrought-iron or steel stampings. Although malleable-iron castings are extensively used for the purpose, their use cannot be too strongly condemned, as it has not unfrequently resulted in the total collapse of the machine while being ridden. The temptation to substitute malleable-iron castings for wrought-iron or steel stampings is great, on account of the crying demand for novelty in the construction of tricycles; and when it is considered that the existing patterns are constantly being superseded by new ones, which in their turn will be cast aside for further improvements, it will be seen that the cost of the new tools and stamps required, which must be charged to the cost of the tricycle, is very great; and the author believes that this is the real cause of the present high price of tricycles. When these have reached the same degree of perfection as bicycles, the prices of the standard patterns will doubtless adjust themselves to a lower level.

Steering Gear.— The steering gear may be dealt with under two heads:— 1st, the method of mounting the steering wheel, so that it may be turned for the purpose of steering; 2nd, the method of controlling the wheel.

1st. The steering wheel of all bicycles and of most tricycles is carried in a vertical fork, at the top of which is a socket or head whereby it is connected to the other part of the frame, so that it may be turned for the purpose of steering. There are two varieties of heads, the "socket" and the "Stanley."

The socket head, which was the first used, is constructed as follows. From the top of the fork rises a pin tapering gradually upwards, and provided with a screw thread and nut at the top. Upon the pin is fitted a taper socket, attached to the other part of the frame, and adjusted and kept in place by the not on the top of the pin. There are many objections to this make of head, and it is fast falling into disuse, being superseded by the "Stanley" head, so called from the name of the machine on which it was first used.

In the Stanley head, as illustrated in Fig. 88, the top of the fork is formed with a cylindrical socket H, in tire back part of which is a slot. Within the socket is placed a short spindle S, attached to the frame of the machine by a narrow web called the neck N, which passes freely through the slot in the back of tile socket. The ends of the spindle S are coned, and work in corresponding coned bearings; the bottom bearing which carries the load is in the bottom of the socket, and the top bearing is in an adjustable set-screw or cap screwed down into the top of the socket and secured by a lock-nut. The spindle S is made as long as possible, in order to give increased steadiness. Sometimes balls are introduced between the coned surfaces, as illustrated in Fig. 89, in order still further to diminish the friction. In Fig. 90 is shown a modification of the Stanley head, in which a pin C is passed down through the neck-spindle B, and is screwed into a steel cup E fixed in the bottom of the head A. After the head is adjusted, the pin C is locked by the split coned nut at top. This arrangement gives increased rigidity and wearing surface, and consequently the head is less liable to wear loose and shaky.

Some modifications have been introduced in the method of mounting the small steering wheels of tricycles, chiefly with the object of using a larger steering wheel and of increasing the rigidity of the frame. One such plan consists in mounting the wheel in quadrant bearings, as illustrated in Fig. 91. In another method,

[Section missing from original]

more bars B; and it is mounted on ball bearings upon a short hollow stud-axle A, with a suitable cap C at each end for adjusting the bearings. The hollow axle is itself pivoted vertically at the centre of its length upon an internal bar D, the ends of which are fixed in the frame of the tricycle. The wheel is steered by the horizontal arm E projecting from one end of the hollow axle, whereby this axle can be swivelled horizontally upon the bar D through the extent of the clearance between the bar and the bore of the hollow axle. Either of these two arrangements enables a large steering wheel to be used without adding to the weight of the frame.

2nd. Of the means of controlling the steering wheel in an ordinary bicycle little need be said, as it consists of a transverse handle-bar fixed on that part of the head which is attached to the fork carrying the steering wheel. Safety bicycles that are not controlled like ordinary bicycles may be classified under tricycles.

The ordinary method of steering a tricycle is by a rack and pinion. The pinion is fixed to a vertical handle, mounted in bearings so that it can revolve; and the rack forms part of a light rod, the free end of which is connected with an arm fixed on the fork of the steering wheel. This method of steering is illustrated in Figs. 27, 30, 48, &c.

[Section missing from original]

side, the V shaped cam is forced out of the groove; and consequently its tendency is to re-seat itself, and so bring the steering wheel back to the straight line.

Brake.— Both for bicycles and for tricycles there are but two varieties of brake:— the spoon brake, and the band brake.

The spoon brake, which is now almost the only one used on bicycles, consists of a spoon lever so pivoted that it may be brought to bear upon the circumference of the driving wheel, or of both the driving wheels if used on a tricycle. On a bicycle it is worked by a hand-lever pivoted to the handle-bar, so that it may be grasped by the rider without releasing his hold of the bar. By proper proportion of leverage a great power is obtained; so much so that, unless care is exercised in applying the brake, the driving wheel will be suddenly stopped and the rider will be thrown off.

The band brake, which is the one now used on nearly all tricycles, consists of a steel band lined with leather, and encircling a drum that is fixed on the driving axle. The ends of the band are connected to a hand-lever, by which the band is tightened round the drum so as to exert the necessary retarding force. In some of the central-geared tricycles the band brake is applied to the pedal crank-axle, and is put on by the foot, as illustrated in Fig. 93. This arrangement proves a valuable addition to any tricycle as an emergency brake.

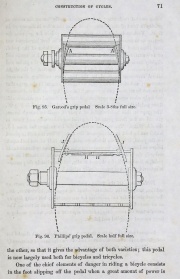

Pedals.- The pedals of all bicycles and central-driving tricycles arc similarly constructed, being mounted on pedal pins which are bolted to the cranks. On the cranked axles of side-driving tricycles the pedals are mounted direct on the cranks, and have therefore to be made in two halves so that they may be put on. In many cases the pedals are mounted on ball bearings. Pedals are made in two varieties, known as rubber and rat-trap: the former have rubber surfaces, which absorb a great deal of the vibration; the latter have roughened steel plates set on edge, and give a better hold for the feet, but are not so comfortable in use as the rubber pedals, as they do not absorb the vibration. Some years ago the author designed the combined rubber and rat-trap pedal illustrated in Fig. 94, which is constructed with rubber bars on one side and rat-trap plates on the other, so that it gives the advantage of both varieties; this pedal is now largely used both for bicycles and tricycles.

One of the chief elements of danger in riding a bicycle consists in the foot slipping off the pedal when a great amount of power is being exerted in driving; and as this instantly throws the centre of gravity in front of the driving-wheel axle, the rider is thrown off in front. Various devices have been fitted to pedals for gripping the feet, so as to remove this source of danger. The first introduced was that illustrated in Fig. 95, in which the side plates of the pedal, or two auxiliary plates A A fixed to them, are curved upwards and slightly inwards, so that the foot jams itself between the plates and is held secure. But this is found to deprive the foot of the slight lateral movement required by the leg when exerting downward pressure; and often the foot gets so tightly jammed in the grips that it cannot be released quickly enough for enabling the rider to dismount suddenly when occasion requires. After an extended experience with these pedals the author designed the grip-pedal illustrated in Fig. 96. The grips on this pedal consist of a pair of small bell-crank levers, pivoted on the front plate of the pedal on either side, and close to the side plates. The vertical arms of the levers have fiat jaws J J, which can be bent to the shape of the foot. When the foot is placed on the pedal, it bears on the horizontal arms H H of the bell-crank levers, and causes their vertical arms with the flat jaws to turn inwards and grip the foot: so that, as long as any pressure is exerted on the pedal, it is impossible for the foot to slip, but immediately the pressure is removed the foot is automatically released.

Fittings, &c.— Of the fittings and accessories of cycles, such as saddles, lamps, bells, distance-indicators, spanners, lubricators, etc., the varieties are far too extensive for enumeration; but many display an amount of ingenuity which will repay an inspection of them. The manufacture of these fittings forms separate trades, which employ a large amount of capital and labour.

In conclusion the author desires to acknowledge with thanks his obligations to those manufacturers and others who have so courteously rendered him every assistance fur the preparation of this paper.

See Also

Sources of Information