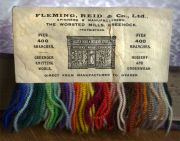

Fleming, Reid and Co

Fleming, Reid and Co of Worsted Mills, Greenock

1899 The company was registered on 8 February, to take over the business of worsted spinners of the firm of the same name. [1]

c.1960 Acquired by J. and P. Coats, Patons and Baldwins

MESSRS. FLEMING, REID & CO., LIMITED, WORSTED MILLS, GREENOCK.[2]

[p277 and p279. See image for full text]

In the year 1840 Mr. John Fleming and Mr. James Reid started in partnership a small mill for the making of worsted yarns in the town of Greenock. Mr. Fleming was the son of Mr. James Fleming, of Newlandsfield, Glasgow, and therefore had good connections in Glasgow. Mr. Reid also possessed advantages which helped to give the young business a start. At first their trade was chiefly with Glasgow manufacturers, and for a time they prospered. Glasgow woollen trade declined, however, and the outlook was not very lively for the Greenock firm. Fortunately, just at that time the carpet trade received an impetus from the invention of the tapestry carpet, and Messrs. Fleming, Reid & Co. went in for the making of carpet yarns.

This was a new beginning for the firm. About the same time the firm received important accessions in Mr. A. M. Fleming, younger brother of Mr. John Fleming, and later Mr. James Reid, nephew of Mr. Reid, as junior partners. Mr. A. M. Fleming was many years younger than his brother, the senior partner of the firm. Born at Newlandsfield, he attended Glasgow High School, though the distance between his house and the city was then considerable and without the facilities for communication now existing.

After finishing his education, Mr. A. M. Fleming entered the employment of Messrs. Fleming, Reid & Co., and voluntarily undertook a thorough training in the manufacturing business. He took a comprehensive grip of the practical needs of the concern, and manifested such sagacity that he was very soon allowed to exercise managing control and assumed a partner. The later developments of the business and the successes achieved owe a good deal to Mr. A. M. Fleming's initiative and business foresight.

In 1899 the firm of Fleming, Reid & Co. was formed into a limited liability company, and Mr. Fleming was offered and accepted the chairmanship of the company, a position which he still holds. His son, Mr. James Fleming, is managing director of the company. Mr. James Reid was born in Belfast and educated at Belfast Academy and Queen's College.

In the year 1859 he came to Greenock, and entered the employment of Messrs. Fleming, Reid & Co. he received a thorough training and insight into the commercial department, and at the end of six years was made a partner. Mr. Reid has always taken a keen interest in politics, not simply for the advantage of the party to which he attached himself, but because he sincerely desired the welfare of the people generally. This was shown in the active part he has taken in the management of local charitable institutions and benevolent agencies. He thus unwittingly won a popularity in Greenock which issued in his election to represent the town in the Imperial Parliament. In addition to being M.P. for Greenock, Mr. Reid is a J.P and Deputy-Lieutenant of Renfrewshire. When the firm was formed into a limited liability company Mr Reid accepted the position of deputy-chairman of the board of directors, thus retaining his connection with the business while freeing himself for the discharge of his political duties. Messrs. Flemingg, Reid Co. have not been without those incidents which go to make history.

In 1880 their mills were almost wholly destroyed by fire, the warehouse alone being saved. Within two years their splendid new mills were erected, and work resumed at higher pressure than before. During the interval the firm rented mills in England, where they carried on manufacture, and supplied their customers as if nothing had happened to disturb the current of business. Difficulties overcome seem to stimulate to further effort.

In 1883 Messrs. Fleming, Reid & Co., finding some difficulty in developing their trade in worsted yarns, resolved to appeal directly to the public, and established retail branches in various centres of population. The move brought immediate success, and now the firm has 128 branches throughout the United Kingdom.

A further step was brought on by the development of the retail trade, namely, the manufacture of hosiery. This department, though the youngest, is not by any means the least prosperous of the firm's ventures. The importance of the step which this firm of manufacturers took when they resolved on dealing directly with the public is considerable. Economic science requires that producer and consumer should be brought into immediate relation, if possible. In pursuit of purely practical ends, Messrs. Fleming, Reid & Co. have put into practice a great economic principle, and have profited largely thereby. In fact, they not only conquered a superstition in the worsted yarn market that threatened their existence, but they also gained a fresh and invigorating sphere of activity.

Greenock Worsted Mills are beautifully situated nearly on the ridge of the hill overlooking the port. The buildings are massive and extensive, a long range of two-storey buildings in front, with the mass of the mill, six storeys high, behind, making an impressive picture. The front buildings are occupied by the counting-house, typewriters' and clerks' offices, the managing director's room, and other kindred apartments, while on the second storey are the large board-room, a clerks' tea-room, and lunch-room for directors and managers.

At the back of the mill the engine-room is situated. Here the whole motive power of the mill is developed by an 8-ft. Swiss turbine water wheel. The water comes down from Loch Thom, and is led through a 42-in. pipe to the turbine, the force of the stream being concentrated by a gradual tapering of the pipe. Beside the turbine are large rope drums which transmit the power to the mill, conveying without appreciable loss 600 horse power.

The wool is brought to the mill in bales and taken to the sorting depart relent, where the fleeces are separated by skilled sorters into the various qualities. Not only do different breeds of sheep produce different kinds of wool, but there are varieties in the quality of wool contained in a single fleece. The wool sorter, therefore, performs no light service. Laid into baskets by the sorters, the wool then carried to the scouring-room, a long apartment lined on both sides by a series of iron cisterns containing the scouring fluid and fitted with scouring appliances. At the one end the wool is fed on to a moving lattice that carries it forward to a deeply bevelled roller, which, in turning, plunges the wool into the cistern.

In the cistern a series of forks work the wool forward to the other end, where the scoured material passes between heavy rollers that press out the moisture and drop it into the receiver. To dry the wool thoroughly steam-heated driers are prepared. These resemble large steam chests with fans inside that drive the heated air through perforated covers, whereon the wool is laid, the hot air thoroughly permeating the mass and drying it quickly.

Having been dried, the wool passes on to the carding room. This is a spacious apartment, wholly filled with carding machines, looking like rows of living mammoths tirelessly labouring. Carding machines are designed to separate the fibres of the wool, and chiefly consist of wide cylinders and rollers all covered with fine teeth, which, by their mutual operation, gently open out all the knots and tufts in the wool and deliver it in the shape of an endless thick strand or rope. Though admirably devised for opening out the fibres, carding machines cannot give them direction, and to make good yarn all fibres of wool must be straight together. Therefore the ropes of carded wool are wound into balls, and in that form fed into the combing machine, one of the most ingenious inventions used in the wool manufacturing process. This machine not only straightens all the fibres, but also discards the short wool. It is circular in form, wheeling round and round, the wool running through the fine combing teeth and emerging in the shape of a thick thread, which is wound on to large bobbins.

These bobbins are conveyed to the drawing department, where they are placed on the drawing frames, and again wound on to bobbins. But between the first and second set of bobbins are two rows of rollers, the first row running more slowly than the second, and as the passage of the wool is regulated by the revolution of the rollers the second set of rollers must lengthen out the wool, because they draw much faster than the rollers supplying them.

In the succeeding departments, long, high rooms filled with ranges of machines, the process of thinning the thread goes on until it is brought to the fineness required. Now the wool is brought to the spinner. The spinning differs from the drawing in that the spinning machine not only makes finer the thread, but gives it a close twist that strengthens it and gives it consistency. The difference between the drawn thread and the spun thread in tensile strength is very remarkable. Twisting machines have a ring on the spindle fitted with a little steel link that catches the thread and takes it round the ring at a great speed, thus giving it a very close twine. Some of the spun thread is destined for warping, some for weft, but the larger proportion of the spun wool here goes to make knitting yarns. For that portion the process of twisting, the combination of two or three, or four or five threads into one, is necessary. This process is done on frames similar to spinning frames, with slight differences in detail.

Warping machines are high fence-like structures into which bobbins are fixed; the thread is drawn off the bobbins, and, passing through a regulator, is wound on to the weaver's beam. The yarn destined for weft is reeled off the bobbins on to reeling frames, and made up into hanks or heads, as they are called. Into the details of the yarn washing and dyeing processes we have not space to enter. The washing machines are long troughs above which run roller-like arms. On to these arms the hanks of yarn are laid, and rinsed through the trough, then laid in a gigantic wringer, which effectually squeezes out the water.

Dye-vats of all colours range along the dye-house, and dyeing appliances of the most modern kind stand to the hand of the dyers. Dyed and dried, the knitting yarns are again wound on to spools or bobbins, some in combined shades and colours, some in simple blacks or reds or greens, then passed on to the knitting or hosiery department.

The main portion of the mill is praiseworthy for its ample spaces and height of ceilings, but the hosiery buildings are specially to be admired for their lightness, ventilation, and cleanliness In spacious rooms long rows of girls are sitting, each with a knitting machine before her. The knitting machine is quite a modern invention, and might almost be deemed new even in these days of rapid change. A fanciful friend of ours suggests that the origin of these machines seems very likely to have been a toy greatly used by the schoolgirls of a generation ago. It was a cork with a hole in the centre, and round it stuck six. pins; the wool was looped round the pins, and then, another loop being twisted' on top, the lower loop was lifted over and became part of the knitted strand that was formed in the centre of the cork' and drawn down through the hole. The theory is a pretty fancy, and may pass for that. Such, at any rate, is the principle of the knitting machine; the cork is an iron frame, the pins are rows of needles; for the deft fingers of the schoolgirl little hooks of steel are substituted, while instead of a mere thick strand of wool appears the shapely stocking.

The knitting machine, however, has been improved almost beyond recognition. In these rooms there are hundreds of ordinary knitting machines; but there are also scores of machines that might almost be called weaving looms. Several very pretty ones have the harness or tambour attachment whereby tartan and other intricate patterns are automatically produced; others again send out from the intricate combination of needles and little steel fingers fine shapes of knitted underclothing. The trimming machines cut off the superfluous "cloth" and sew on the trimming at the same time. Then there are pretty crocheting machines, making those fantastic loops and scallops dear to the feminine mind with a rapidity and deftness very wonderful. The hosiery mechanical inventor has been late in coming, but from the specimens of his art in Messrs. Fleming, Reid & Company's works, it appears that he has chosen his time well, and levied the mechanical world for his own use. Messrs. Fleming, Reid & Company seem to spare no expense for the comfort and benefit of their workers. For those who prefer their meals at the works there is provided an ample spacious dining-room. It is also worth noting that there is here a school for the half-time children, who attend school and work on alternate days, under Government inspection. On stormy days the children are provided with a hot meal in the middle of the day, so that they need not go home. There are other details in connection with these works which night well be mentioned, but our space forbids. Over their 700 employees Messrs. Fleming, Reid & Company exercise a judicious control, which, while respecting the individual liberties of the workers, makes them feel that their employers know and sympathise with their difficulties.