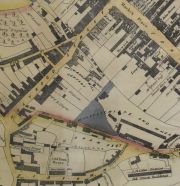

Holyrood Lace Mill, Chard

in Chard, Somerset

1827 Mill constructed [1]

1830 Sale Notice: 'IMPORTANT SALE. LACE MANUFACTORY, CHARD, SOMERSETSHIRE.

TO SOLD BY Mr. PATCH, at the Chard Arms Hotel, in Chard, Somerset, Wednesday the 7th April next, at 4 o'clock in afternoon, by order the Assignees of SAMUEL SPARKS, a bankrupt.

An extensive LACE MANUFACTORY, in Holy Rood-Street, in the borough of Chard, standing on a piece of ground containing about half an acre, surrounded by walls, with the Steam.Engine, Power Machine, Smith's Forges, Lathes, Apparatus and Fixtures belonging to the above establishment. The Manufactory is newly and substantially built, Fire-proof, the Pillars, Beams, and Roof, being of cast-iron, and having stone or brick floors. It 95ft long, 37 wide, and 56 high, and has five floors of the following dimensions.

First Floor, 72 feet long by 32 feet wide, with Gearing fixed, and shafts, sufficient for 36 Machines. Stair Case.... ..... Also, 2 twelve quarter Frames, in a forward state, a 16 horse steam Engine, of excellent workmanship, and connecting gearing for two rooms; two Boilers used alternately with gearing complete, and in good condition. The Machinery is in excellent preservation, having been constantly at work. ....'[2]

1832 Draper and Co were the proprietors [3]

1838 Sale Notice: 'For Sale by Private Contract, A Large and Substantial Lace Factory, with Steam Engine, Machinery, commodious Dwelling House, and every other accommodation for manufacturing on an extended scale, situate in a populous town in the West of England. The Building is brick and fire-proof, containing five floors, 95 feet long, 37 wide, and 56 feet high, and the Machines (43 in number, of Blond, Plain and Quillings), are Twelve-quarter Circular Bolt, Rotary Motion, with double Sets of Brass Bobbins and Carriages, made upon the most approved principle, and in complete repair. For particulars apply to Mr. WEBB, Holly Rood Mill, Chard, Somerset.'[4]

1839 'Dreadful and Fatal Accident. —lt is a long time since we have heard of a more distressing death than the one below detailed, which occurred on Monday evening last in the lace manufactory of Messrs. Hill and Company, Holyrood-street, Chard. The victim was an industrious carpenter aud mechanic, named Robert Hayball, about 52 years of age. He went into the factory about five o’clock, for the purpose of fixing a heavy grindstone on the second floor, which it was intended to propel by means of a belt attached thereto, and to the shaft of an engine of 16 horse power. The belt was temporarily put round the drum-wheel through which went an iron shaft, at the distance of a foot from the ceiling, the engine being in full motion. He got a piece of chalk to mark the number of revolutions it performed in a minute, which was supposed to be nearly 70. Scarcely, however, had he extended his arm for the purpose, when the belt, which was so slack as to form a loop, drew him, with surprising velocity, to the ceiling, and at the next instant his left leg was found at nearly a dozen yards towards the other end of the room, broken off at the knee. His right hand and part of the arm below the elbow fell under him, while the other leg was wound like a cord two or three times round the shaft, the boues being snapped asunder at various places. Before the engine could be stopped the rest of the body must have gone round between the two shafts at least 40 times. The body was so firmly fixed that it was necessary to amputate the already mangled arm at the shoulder ere it could be extricated from its horrible position. The deceased felt his danger, but had time to make only one exclamation as it rapidly approached. A dreadful blow to the right side of the head above the forehead, as it came in violent contact with the ceiling, relieved him from all but momentary suffering; it was a sudden and terrible shock, with which life instantaneously fled. The son of the deceased was near, but he had not power to save his father; yet it is a most singular circumstance that about an hour previously he rescued an individual, named Webb, from similar death, by pulling him back by the legs after the belt had laid hold him. Bath Chronicle.' [5]

1852 Mill bought by James Benjamin Gifford.

From c.1857 the mill was occupied by Gifford, Fox and Co, lace manufacturers. Five storeys, 'fireproof' construction.

The ground floor and first floor are now occupied by Chard Library.

Beam Engine

The mill's beam is preserved in the USA. Its maker and construction date are not known.

The engine was photographed by George Watkins, probably before 1945[6]. Maker unknown. 35-40 HP at 35 rpm with steam at 30 psi. Drop expansion valve worked by a cam on the crankshaft, possibly added to suit increased boiler pressure. Bevel gear on crankshaft, with wooden teeth. The flywheel was made in sections, with eight castings each having an arm and rim sector. The rim sectors, of circular cross-section, were butted together and connected by links located within sockets. The ends of the spokes fitted in sockets in the hub casting. Governor said to have been added in 1857.

The engine is recorded as having been bought second-hand from Sheppard's Spring Gardens Mill in Frome. There is some evidence to suggest that the installation work was done by Robert Lee of Frome. In 1958 it was shipped to the Wilkie Foundation's Headquarters in Des Plaines, Illinois, USA.[7]. Leighton Wilkie, the founder of the DoAll Corporation, had bought the engine from Fox, Gifford.

Photographs of the beam engine in the USA, and a discussion of its history, are available here[8] and here[9]

In 2006 the engine was acquired by the Cedar Valley Engine Club, in Charles City, Iowa.[10]

See Also

Sources of Information

- ↑ [1] BODEN LACE MILL & CATTLE MARKET, CHARD. IMPACT ASSESSMENT IN CONSIDERATION OF TOWN CENTRE REGENERATON: LEISURE CENTRE & COMMUNITY FACILITIES for South Somerset District Council, May 2019. Nichola Burley, Heritage Vision Ltd. p.20

- ↑ Sherborne Mercury - Monday 29 March 1830

- ↑ Exeter and Plymouth Gazette - Saturday 15 December 1832

- ↑ Nottingham Review and General Advertiser for the Midland Counties - Friday 15 June 1838

- ↑ Bell's Weekly Messenger, 4 November 1839

- ↑ The Textile Mill Engine by George Watkins, Part 1, Plates 1 & 1a, Landmark Publishing, 1999

- ↑ [2] Somerset Historic Environment Record, 58251: Holyrood Mill, Chard

- ↑ [3] 'A Chard beam Engine in America' by R. Damian Nance, Somerset Industrial Archaeology Bulletin, No. 101, April 2006, originally published in the Journal of the ISSES

- ↑ [4] LITTLE-KNOWN WATT STEAM ENGINE IN AMERICA by R. Damian Nance, Society for Inustrial Archaeology (USA) Newsletter Vol 35 N0. 3 2006

- ↑ [5] Farm Collector online: 'James Watt Steam Engine: Iowa Club Obtains Historic 1799 Item, Boring Mill' by Kelly Barnett and Howard Shanks.