International Combustion: The Early Years

Note: This is a sub-section of International Combustion

How ‘COMBO’ came to Derby - The beginnings of International Combustion by Alan Gifford

The Underfeed Stoker Company

In 1898 an American, W. R. Wood, formed the Automatic Furnace Syndicate, with its head office at 18 Walbrook, near Cannon Hill Station, in London, and the furnace stoker machines they marketed were initially built under some railway arches in East London. This arrangement was soon to be followed by an agreement with the Railway and General Engineering Co of Nottingham to manufacture the product for them. At that time coal fired steam boilers were in use in almost every factory of the country, from textile mills to steel works, from bakeries to brick yards, all fed with huge quantities of coal by hand shovels. The new product, Mr Wood brought in from America was a revolutionary device which mechanically fed coal directly into the hearth of the furnace, - a truly amazing operation in those days.

In 1902 the company name changed to The Underfeed Stoker Company, as more properly describing the product being sold , and manufacture shifted to Slough.

In parallel with this activity a new engineering works, designed to make wood working machinery, was being constructed by a Alan Ransom, at Newark and it was recognised by both parties that the requirements of high quality castings for both woodworking machines and stokers were similar. A deal was done and the Underfeed staff from Slough therefore moved to Newark in 1903 and stokers were designed and made there for the next 25 years. Up to 500 tons of the product was shipped out each month- the business was doing well. But in 1922 the entire Underfeed Stoker operation transferred to a new factory at Derby which was however, initially called for reasons still quite unclear, ‘The Derby Works of International Combustion Engineering Ltd.’

Barrow-in-Furness

Up in the north east other compatible events were occurring, since in Barrow-in-Furness, Cumbria, a small company emerged in March 1924 called Vickers and International Combustion Engineering. This name, soon to be changed to Combustion Engineering, was a company which would specialise on the new concept of producing and burning powdered coal in power stations. The company specialised in a then new concept of using powdered coal for firing power stations, produced by one of two special machines, known as either ‘Lopulco’ Roller Millers or Pulverisers. This black flour-like product was blown into the furnace and burnt, almost like a gas!

The works were in Barrow and was set in a beautiful location by the shores of the Walney Channel, but design and sales operations were both London based. The works were under the direction of Mr Mc’Highton, who soon had problems when local housewives found their washing often turned black with powered coal dust from the test facility! After about 12 months a local drawing office, under the control of Mr Phillip as head draughtsman, was set up and designs were evolved for roller mills producing up to 15 tons per hour of coal powder - an unheard of amount at that time! Miss Pope was the first typist, Miss McConnell the first tracer and Mr J. P. Gillver joined the Accounts Department whilst the first two apprentices taken on were Mr A. Rodger and Mr A. Hingley, all of those named later came to Derby. (Photo 1/ Barrow Machine Shop, 2 /Barrow Mill Assembly)

One of the apprentices, although employed slightly later, was Ralph Belshaw, better known to all as ‘Curly’ , who was apprenticed from 31st May 1926 (with the Vickers Co. see above) for five years to be trained as a sheet metal worker. By the agreement he was to be paid 7s 6d a week in the first year, rising to 18s 0d in the final year, but if by good conduct and diligence he excelled, the rates would rise by a further 3s 0d a week. In 1928 he was being paid 25s so he must have exceeded the required criteria! Curly was also one of those who was later transferred to Derby and became a well known figure in the Plate Shop for many years to come. ( He died in 2003 at the grand old age of 93.(3/ Curly Belshaw Plate Shop late 1950’s)

By 1927 the limitations of the works were becoming apparent, there was too much direct dependence for certain operations on Vickers manufacturing equipment and many home made devices, such as a plate bender, were constructed. The problem was recognised however and a site for a new works was chosen near Barrow. However behind the scenes there had been major dialogue between the Manager of Underfeed Stokers, Mr R. Greenwod, who had already moved from Newark to the new works at Derby and Mr Usher (later to be Sir) George Usher. It was eventually agreed that the Barrow based company would also move to the new works at Derby and that the two companies would merge, becoming International Combustion, based at Derby, but with a London Office, in Wobourn Place (hence the mystery as to why the works were initially named International Combustion Engineering Ltd)

So what was the new works like and where exactly was it?

(NOTE, Two quite extensive reports, have recently been found in the journal ‘Engineering’ which describe, and illustrate, the initial building of the works in 1923 and then continue, in 1928, to show how they were soon extended. In addition Vic Belshall, the son of Curly, mentioned earlier, recently found and shared with me a collection of the old company house magazine ‘The Peak’ which fortunately contained a number of first hand reports on the early days of the company. These reports together form the basis of this article.)

Factory in the Countryside near Derby?

Sinfin was first mentioned in charter roles of 1251, as Sydene Fen, meaning Broad Fen. For ages it remained as a hamlet of scattered small cottages and farmsteads situated on the edge of a bleak area of marsh and moorland. In February 1922 it was announced that a large engineering works was to be built on these dismal lands and that some 50 acres (later 62) had been acquired for the purpose. The site was selected purely on economic grounds, the land being cheap and the rail communications with the rest of the country very good, thereby minimising transport costs

In those days ‘Sinfin Lane’ truly was as lane, a twisting muddy cart track, with branches off to the various farms. The side of the lane away from the Barracks was bordered by a steep tree-grown bank which continued until about opposite the entrance into the works ,where there was a small row of cottages on the site of what became Hampshires, the chemists manufacturer. No buses ran down the lane, only an infrequent service from the town to the Barracks! Beyond the works a stream crossed the lane, at a hump back bridge, and meandered off across what is now the golf course.

The first sod for the new works was cut through a hedge to provide an entrance into the site was beside a large oak tree, which soon had to be felled. There was also some early trading between the blossoming new works and Richardson’s, the tannery by the railway bridge whose old brick kilns site were brought into use to store the stream of machines which were constantly arriving, many of which were purchased second hand at first world war disposal sales. Incidentally the bricks for Barracks, built some 50 years earlier were made at the old brick works and the nearby clay pits were reputed to be 80 feet deep!

The New Works Emerges - 1922-23

The first building on the site was a corrugated iron hut, with a floor made of discarded railway sleepers, which was soon populated by rats. There was no sanitation, heating ,washing or drinking facilities ; there was one telephone and the only service was provided by a ‘mashing’ lad, who boiled the water on a brazier and was required to provide a constant supply of tea! In the lane there were often queues of up to several hundred men, all waiting patiently in the hope of obtaining a casual labouring job. Mail was delivered once a day by a post man who always made the works his last port of call ,after covering Barrow, Arleston and Stenson. When challenged he was aghast and said this was the route he had followed all his life, and his father before him, and he was not changing his ways!

A key feature of the mandate to the designer of the workshops , Mr A. W. Farnsworth, was that that he should maximise the use of natural light. Previously this had always presented problems, since such buildings tended to be hot in summer and cold in winter and it was never easy to keep the glazing clean. The design he adopted claimed to have overcome these difficulties. Additionally the basic design of the steel structure for both the machine shop and the foundry had to be the same.

Foundry work was a key feature in the construction of mechanical stokers and similar devices which were the initial products and provision of a foundry was considered essential to a successful business. Two 15 ton and one 6 ton cupola for producing cast iron were used ,and large storage areas were allocated for all the required raw materials. The 15 ton cupola’s were to be amongst the largest in the country at that time,

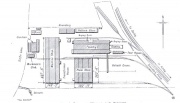

The initial build was of the machine shop, a foundry, a pattern shop and a small office unit, including a drawing office. A separate boiler house for heating and transformer /switch gear connected to power supplied by Derby Corporation were also included.. The internal roadways were surfaced with only with rolled ash. The main transport link the railway had sidings connected directly to the Midland Section of the L.M & S railway whilst ,the lines ran directly into the shops to facilitate loading.

The machine shop was 226’ long and by 150’ wide whilst the foundry was larger, at 262’ long but the same 150’ width. Each of the buildings had one central bay with a 60’ span and side bays with spans of 45’ , all of which were 32’ to the eaves. The machine shop was said to provide 33,500 sq feet of working area, whilst the glazed wall area was bigger, at 34,100 sq feet, although there was no glazing in the lower 6 feet, to minimize the risk of glass breakages and to facilitate installation of machines, benches etc.

There were large lanterns in the apex of each bay, each fitted with multiple ‘swinging sashes’, which could be opened or closed from ground level. In addition numerous opening hoppers were fitted in the side walls to help control ventilation. Rainwater from the roof was taken down inside the main building supports and then fed directly into the site drains and there were walkways in the roof provided so the glass could be cleaned - occasionally one suspects!

Just to the north of the foundry was the large pattern shop and store where wooden shapes for all the many castings, both large and small, were carefully produced by skilled craftsmen, who had to work with special rulers which allowed for the shrinkage which took place when the molten iron cooled!10/ ICL pattern shop 1923,

Two electric powered travelling cranes were installed in all bays and there were numerous ‘swinging’ hand powered cranes provided to quickly free the main cranes. Handling outside was by two steam powered mobile cranes, which ran on the rail tracks, and they could be driven directly into the shops.

Heating for the site was by four low pressure steam boilers and it was claimed that a temperature of 60oF was maintained when the outside temperature it was freezing! All the shops were illuminated by electric lighting , the main bays having 1000 watt gas-filled lamps.

So, by the end of 1923 the basic factory had been established, which was very focused towards the production of castings from the new foundry. The first castings in fact were made on October 2nd 1922, something commemorated by the production of a number of special memorial plaques! A new era was however dawning!

New Vistas- New Name

In the period between 1923 and 28 however the major business changes were taking place to the Underfeed Company (as noted earlier), the name of which was simplified to International Combustion Ltd and the ‘Lupulco’ business, closely associated with the production of, and the combustion of, powdered coal, merged into one company. A big team was to come in from Barrow and major expansion were urgently needed to accommodate these newcomers! The early workshops and offices, which had only occupied a narrow strip at the north end of the site, expanded to cover more than 20 acres, with the balance of the site still preserved as meadow land.

The office and drawing capabilities more than doubled in size and there was room for 60 draughtsmen and tracers to carry out both general and working drawings. This effort was supplemented by additional drawing and design capability in the London Office, in Wobourn Place, where all proposals and estimates were prepared.

A Larger Machine Shop

As described earlier this shop was originally 150 feet wide and 226 feet long. The width was maintained in the new extensions but the length doubled, to almost 500 feet. Seven new bays were added , similar to the originals except that that the opening fan lights in the roof lanterns were replaced by louvres. The centre bay was served by a 15 ton and two 5 ton travelling cranes, plus numerous 1 ton jib cranes. The southern end of the shop was set aside to be used primarily as an erecting shop for the various machines being produced. Following the completion of the new building all the heavy machines were moved into the centre bay, whilst the lighter ones were sited in the two outer ones. Most of the machines were driven by belting from over head line shafting, powered by 20 HP electric motors. A large lathe turned the steel shafts used in the chain grate stokers ,which were up to 26 feet long and 10 inches in diameter! 11/ ICL Machine shop 1929

And an Extended Foundry

The foundry was also increased in size by just under 40%, and was enlarged to 375 feet long. The cupolas from the production of cast iron, were all located in the centre of the north side of building, with spouts for the molten metal leading directly into the shop. These had a capacity of 12 tons of iron per hour and typically 150 tons per week was being produced at that time, an increase of about 50% on previous capacity. Initially there was no form of mechanization and everything was done by hand, resulting in a large labour force! The sand was prepared in the shop and castings ranged in size from a few pounds up to 14 tons in weight. A small non ferrous foundry was built on the northern end to supply all the bushes, bearings etc required for the various machines being built.

A New Plate Shop

A totally new shop was also built in 1928, to supply the structural work associated with the Lopulco system of powdered fuelled boilers which included a great variety of plating and girder work , hoppers, cyclones, fuel pipes, boiler tubes etc. The building was 190 feet wide and 262 feet long, with four bays, three being 45 feet wide and one 60 feet. It was similar in construction to the machine and foundry, with cranes between 2 and 5 tom capacity. The shop was well equipped with shearing, punching, plate and angle bending machines ,together with many radial drills. There was also an early automatic welding machine in the shop, used to produce the welded fin tubes required for the powdered fuel boilers. Tubes 4 inch diameter had two fins ,each 1 3/8” wide by ¼” thick continuously welded on, the two welds being made simultaneously at a then outstanding speed of 7” per minute! Both acetylene and electric arc welding were generally used in the shops, with the former being phased out. Bare wire welding was still used for a while but coated electrodes soon took precedence. (Note- This in fact represents quite an early use of arc welding, at a time when riveting dominated the scene.). Managers of note in the shop were Ted Pearson (but always Peeo!) who came from Barrow ,who was succeeded by Bill Kellie.

To the east of the Plate Shop a new 6 ton Craven travelling Gantry crane was built , working in the open air, which covered an area of 250’ by 600’ feet and greatly expanded the capability to build large plating assemblies, although at times working conditions for the workers were very harsh!

A New Test Department

An entirely new department was also set up ,just beyond the foundry, as a test house, or demonstration plant. It was equipped with several sets of full sized coal-pulverising machines and was used to show customers the benefits of the various devices marketed, such that they could move into this new field with some confidence.

Welfare Facilities/ Conditions of work

The new buildings provided the general manager and works director, Mr R. Greenwood, with a spacious new office, which had windows overlooking much of the works! A canteen, capable of seating some 700 workmen, with a separate area for staff was also provided and it was then a works rule that any food brought in by workers must be left in the canteen area before they started work and no food was permitted to be eaten in the shops! In addition a licensed club room, with billiard tables and other games, was also included; this acted as the headquarters of the various sports activities the works encouraged, such as football, cricket, fishing, bowls etc.

Jobs were few and far between in the early 1930’s, money was scarce, so most people walked to work, whilst a lucky few had bikes, only the Manager himself had a very small car. The Firm had just one vehicle- a light Ford pickup type truck, - painted in what became known for years as ‘Combustion Red’. People just sat in the back of the truck, on boxes, and they often got snow balled in the winter months! The same truck was also used to collect visitors to bring them to the works from the railway station in Midland Road!

There were about 1000 employees in the works at this time, with the hours of the main works being 7-55am to 5-30pm, for 5 ½ days ,whilst the foundry worked 7-30am to 6-0pm, but for 5 days only. There was one week a year holiday, plus bank holidays – no 10 days for Christmas and the New Year then!

And then!

ICL continued to prosper under changing ownership, and became a world renowned name for the production of power boilers, milling plant and other similar equipments. It worked especially hard supplying military equipment during the war and afterwards built hundreds of boilers, large and small (up to 600MW) across the world. The company also provided much specialist equipment for nuclear power plants and became the work place for a large work force of up 2000, including many generations of Derby people. The company enjoyed very long periods without industrial relations problems , quite a success when there were also to 1200 men employed on short term contracts erecting the plant on site.

Purchased by Rolls Royce during the late 1990`s, ICL became mainly involved in the fabrication of co-generation power plant, to other companies designs, by the provision of the waste heat boilers heated by the pass-out gases from gas turbines. Although lucrative, this plant was not to be compared with the glory days of the large coal fired boilers.

A change of policy by Rolls Royce led to a reduction in its exposure to the power industry, thereby reducing ICL to little more than a fabrication shop. Much of the site has now been cleared and, with the company name, along with the design expertise having been sold off, what remains today in Sinfin Lane is just a shadow of its former self!

Alan Gifford - March 2008

See Also

Sources of Information