G. Kynoch and Co

Kynoch Limited of Lion Works, Witton, Birmingham

- 1834 George Kynoch was born at Peterhead, Aberdeenshire.

- 1850 Company established.

- 1856 Kynoch joined Pursall and Phillips of Whittall Street, Birmingham, manufacturers of percussion caps.

- 1859 Catastrophic explosion at the company on September 27th, killing 19 of its 70 employees including children, gravely injuring many others, devastating the factory and damaging the surrounding area.

- 1861 Mr Pursall applies for and is granted permission to build a powder magazine and percussion cap manufactory on a 4 acre site at Witton, a country hamlet in a safer location.

- 1862 George Kynoch took over the Pursall and Phillips business. Kynoch began to manufacture percussion caps at the Lion Works, Witton, Birmingham, later going on to manufacture metallic ammunition.

- 1870s Moved to the Lion Works.

- 1870 The fourth explosion at the factory in two years was reported, this one on November 17th killing eight and injuring twenty, including children. On December 9th an even more appalling accident occured in the neighbouring cartridge factory of Ludlow and Co - possibly a Kynoch licensee - when 17 people were killed instantly and 34 more died later from their injuries; a national outcry ensued.

- 1872 George Kynoch purchased a further 19 acres of land.

- 1877 A rolling mill was leased in Water Street, Birmingham.

- 1882 George Kynoch owned the second largest ammunition factory in Great Britain on a site of 24 acres, a brass rolling mill elsewhere in Birmingham, a patent lamp business, and a printing office. Daily cartridge capacity was now 400,000 and there are 800 employees. He was about to buy a gun factory and he had even bigger plans for the Lion Works factory and also for political and public service - requiring more money and more personal time.

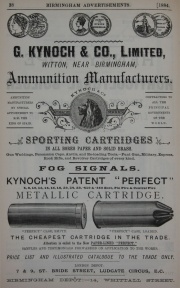

- 1884 The company took limited status. The company was registered on 16 July, as G. Kynoch and Co, to take over the business of the firm of Kynoch and Co, sporting and military ammunition manufacturers. [1]

- 1886 The new company structure was not proving a success and the company was in serious decline. George Kynoch was elected Conservative Member of Parliament for Aston.

- 1888 The disputes between George Kynoch and the Board come to a head and he was forced to resign. Arthur Chamberlain joined the Board and was appointed Chairman. He would serve for the next 25 years.

- 1888/9 Two unsuccessful Kynoch enterprises were disposed of: the lamp factory and the gun business. The metal rolling plant in Water Street, owned by George Kynoch, was bought by the company and an option to purchase was obtained on a larger mill in Lodge Road. These moves gave the Company security of metal supply and control over quality. Work was started on a new .303 plant, a Q.F. (quick-firing shell) factory and a fuse-making department. Determined measures were taken to improve quality control. 85 acres of extra land at Witton and Streetly were obtained in order to provide improved magazines and adequate proof ranges. Attempts to change the factory name from Lion Works - too closely associated with George Kynoch - to Witton Ammunition Works were however unsuccessful.

- 1891 George Kynoch died in self-imposed exile in South Africa.

- The Company was complimented by H.M. Chief Inspector of Explosives on its safety arrangements. In addition to its military ammunition work the Company was producing half a million sporting cartridges a week.

- The Water Street mill was closed and production concentrated at the developing Lodge Road factory; a cupro-nickel casting shop was built at Witton; and a part-time consulting metallurgist was appointed.

- A serious dispute halted production and all 3,000 employees joined the strike which had started over the alleged malpractice of a foreman in using apprentices to do the work of skilled toolmakers. Despite this the Company was generally recognised as one which paid well and treated its employees in an enlightened manner.

- 1893 Kynochs entered the field of high explosive production by purchasing a Yorkshire company, Shortridge and Wright.

- 1895 A new factory was built on a 170 acre site at Arklow on the east coast of Ireland to produce cordite. Very quickly gelignite, dynamite and Kynite were introduced to the product range. A second factory was soon planned, this time on a 750 acre site in Essex, christened "Kynochtown". Glycerine would also be produced at the Lion Works, together with soap and candles (7-8 tons per week) made from the by-products of glycerine manufacture.

- A Siemens-Martin steel melting plant was installed at Witton to supply Birmingham manufacturers with a variety of steel castings and to permit the manufacture of shells of various types including armour-piercing. A new Bullet Shop was created. Witton's first rolling mill was laid down together with a casting shop. Its purpose was to satisfy Lion Works's need for the brass required for ammunition production, leaving the Lodge Road factory to concentrate on trade with third parties. The Company was rolling 100 tons of brass a week. There were also plans for setting up plant to make bicycle components.

- 1896/7 Directory: Advertiser. More detail [2]

- 1897 The shareholders were warned that the Company would need to raise further capital to finance this rapid rate of development. They willingly complied and a new company was formed, Kynoch Ltd with a nominal capital of £500,000 and with Chamberlain still its chairman.

- 1897-8 A period of further rapid development. At Witton the new bicycle plant was producing 200 sets of components (hubs, pedals and brackets) each week. Large additions were made to the ammunition plants. Lion Works was for the first time equipped to cast and roll all of its cartridge brass. Production of candles reached 60 tons a week. A Kynoch machine gun was introduced.

- 1900s By the early years the firm had ten factories in Birmingham, Kynochtown in Essex, Barsnley and Ireland, producing explosives, engines, paper, soap, candles, brass, copper and all kinds of shells.

- 1901/2 Kynoch acquired various new businesses and premises: the Eyre Street factory of Hadley and Shorthouse, producing nails and brass and copper tubes and wire; a large factory at Stirchley to produce armour-piercing and shrapnel shells; Forward Engineering Co adding gas engines to their range of machine guns and roller bearings; a paper mill in Ireland; and perhaps most significant of all Accles of Holford Works, a run-down ammunition company on an adjoining 33 acre site.

- 1906 A second Irish paper mill was purchased. Negotiations started on the purchase of a South African explosives factory. New plant to make soap was installed at Witton and at Eyre Street to make tintacks.

- 1906 The trading results for the financial year showed a big deterioration and those for 1907 revealed an 80% fall in profits from their normal level. No dividend was declared.

- Shortage of work led to temporary shut-downs at Witton of the Cycle Department and brass casting workshop, followed by general short-time working except for the steel, shell, soap and glycerine departments. Outside powder suppliers objected to the increasing use by Kynoch of its own smokeless powders in cartridge production on the grounds of unfair competition. Kynoch's response was brutal: henceforth it would only accept orders from its own customers which specify use of Kynoch powder.

- 1910 Acquired Holford Mills that had formerly been the National Arms and Ammunition Co. In 1888 the mill was taken by the Gatling Gun Co for a short time. Later taken over by Accles to make guns but they failed in 1901.

- 1913 Arthur Chamberlain died and was succeeded by his son, Arthur Chamberlain Junior. He disposed of the two paper mills and gave more attention to metal production. The casting and rolling shops had had long periods of idleness but they were restarted and additional rolling plant installed.

- 1914 Manufacturing upon a large scale all kinds of Munitions of War, Sporting Ammunition, Blasting Powder, Fog Signals, Soaps and Candles, Paper, Coins, Metals, Nails, Iron Castings, Cycles, Gas Engines, Suction Gas Plants etc. Employees 5000. [3]

- WWI Took over the Birmingham Metals and Munitions Co. By the end of the war 3.5 billion small arms cartridges had been produced.

- 1918 The company was merged into Explosives Trades Ltd, along with Eley and other ammunition makers.

- 1920 The parent company changed its name to Nobel Industries; Kynoch retained its own name.

- 1920 John Marston Ltd "the manufacturers of the world famous Sunbeam cycle and motorcycle" was purchased by Kynoch[4]

- 1923 Arthur Chamberlain resigned as chairman of the local Board and was replaced by Sir Harry McGowan who was also Chairman of Nobel Industries.

- The South African explosives interests were transferred elsewhere in the Nobel Industries organisation.

- The Witton activities of soap, candles, cycles and general engineering products were abandoned. The site's activities comprised effectively "the ammunition side" and "the metals side". Three departments at Kings Norton, especially involving strip, were re-opened to meet increasing demand.

- 1924 Three more electric melting furnaces were ordered.

- 1925 Investment was made "to fit up the old Machine Shop at Witton to undertake metallic work for sporting cartridges and metal sundries". Copper consumption soon reached 400 tons per month. Despite Eley being the senior partner in the area of sporting ammunition within Nobel Industries, Kynochs succeeded in persuading the Board of Nobels to concentrate all production on the Witton site. The transfer of plant and personnel from Eley's Waltham Abbey factory, and the transformation of production facilities at Witton, was a long and gradual process. The Eley name was preserved by renaming all Nobel sporting ammunition "Eley-Kynoch".

- 1926 A new company was formed: Lightning Fasteners to handle the zip fastener business.

- 1926 The company, as part of Nobel Industries, became part of the newly formed Imperial Chemical Industries; the Witton factory continued as the ammunition manufacturing centre and became the centre of ICI Metals Division.

- 1932 Installed a hot rolling mill.

- 1934 The Strip Mill was producing 500 tons a month and annual Rod Mill capacity had soared to 14,000 tons. Another tube mill, Broughton Copper Co of Salford, was purchased.

- 1935 Witton's own tube mill was commissioned.

- 1962 The Metal Division of ICI was reorganised and became known as Imperial Metal Industries.

- 1977 IMI became fully independent.

- 1993 The Ammunition Division was incorporated as Eley.

Motorcycles

- Kynochs produced motorcycles from 1904 to 1913.

- 1900 Illustrated pamphlet describing the patent roller bearing for shafting. [5]

- 1904 They began with a model fitted with a 2.75hp engine and chain drive. They also built a couple of machines for Hayden, with fuel carried in the frame tubes. The machine also had rear suspension and was powered by a Simms engine.

- For several years there was no more mention of Kynoch.

- 1912 The firm re-appeared with a model fitted with a 3.5hp JAP or Precision engine, BSA two-speed gear or free-engine option, and Druid forks.

- 1913 Only JAP engines were used, either a 4hp single or a 6hp twin, driving a Sturmey-Archer three-speed hub gear. The machine had belt final drive and the single was also listed with direct-belt drive.

Hayden were motorcycles produced in 1904 for F. Hayden of Cheltenham, by Kynochs of Birmingham.

A machine was built that used the frame as a fuel tank. The tubes were larger in diameter than normal, and the oil was carried in a reservoir by the bottom bracket. It had braced forks and a simple form of plunger rear suspension. It was fitted with a vertically mounted Simms 2.75hp engine with magneto and FN carburettor. The drive to the rear wheel was by belt.

At least two examples of the machine were constructed.

See Also

Sources of Information

- The British Motorcycle Directory - Over 1,100 Marques from 1888 - by Roy Bacon and Ken Hallworth. Pub: The Crowood Press 2004 ISBN 1 86126 674 X

- Birmingham’s Industrial Heritage by Ray Shill. Published by Sutton Publishing 2002. ISBN 0-7509-2593-0

- [1] Staffs Home Guard Web Site

- Trademarked. A History of Well-Known Brands - from Aertex to Wright's Coal Tar by David Newton. Pub: Sutton Publishing 2008 ISBN 978-0-7509-4590-5

- ↑ The Stock Exchange Year Book 1908

- ↑ Peck's Trades Directory of Birmingham, 1896-97: Advertisers

- ↑ 1914 Whitakers Red Book

- ↑ The Times, Wednesday, Jul 07, 1920

- ↑ The Engineer of 18th May 1900 p527